Four Activities That Define an Equipment Business

Running an effective construction equipment business requires much more than just buying new machines and using them to move dirt, break rock, mix concrete, hoist and haul heavy loads, drive piles, or lay pipe into the ground. To be effective, a construction equipment business requires multiple persons, departments, and levels of decision-makers working together while also competing for the same resources.

This competitive complexity is manageable through an understanding of the Equipment Cycle.

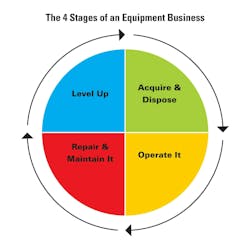

Traditional top-down management and organizational charts are quick to draw lines and divide responsibilities into clear departments such as Operations, Fleet/Equipment, Accounting, Safety, and so forth. Although this helps to empower persons in those departments to take action where responsibilities and accountabilities are clear, what happens when those responsibilities or duties are blurred or shared across departments as is often the case with equipment management? An interdepartmental approach with a deeper understanding of the “business inside the business” is needed. The “business inside the business” consists of four diverse activities that form what I call the “Equipment Cycle.”

How to work the Equipment Cycle

- A smart approach to acquisitions.

- A smart approach to profitable equipment operation.

- Repair and maintain. Coming soon.

- Level-up. Coming soon.

Over the course of any given year, an equipment-intensive company will perform these four distinct activities. It will acquire and/or dispose of equipment, operate the equipment, and perform some level of repair and maintenance to the equipment. The last step, often overlooked to the detriment of many organizations, is that the fleet will engage in a continuous improvement or “leveling-up” process.

Also see Mike Vorster's hexagon describing key asset management functions.

On the surface, one could say that “Operate It” is the responsibility of Operations and “Repair & Maintain It” is the responsibility of some sort of Fleet, Equipment, or Maintenance department. For the most part, that would be correct, but what group or persons are responsible to “Acquire & Dispose” or “Level-Up”? These two activities are crucial to the long-term success of equipment management, yet they often fall between the cracks of most organizational charts. At the end of the day, it truly does not matter what department or position performs each activity, what matters most is the awareness that the activity itself needs to be performed for an equipment-intensive organization to function effectively. The nearby graphic illustrates these four distinct activities. Let’s look with more detail into each one.

Acquire and dispose

In this stage, equipment is acquired and sold. It involves:

- Identifying the equipment needed and what it needs to do. Tasks here relate to standardizing and organizing the fleet which includes setting fleet standards, writing specifications, creating lists for upfitting, and other guidelines.

- Acquiring the equipment and equipment-related items. Tasks here relate to obtaining what is needed, which necessitates efficient procurement practices, using purchase orders, using three bids and a buy to obtain the best price, negotiating volume contracts, managing vendors and inventories, handling warranty claims, and otherwise ensuring reliable supply chains.

- Determining how long to keep the equipment. Tasks relate to managing fleet age which includes establishing target lives, calculating sweet-spot curves, producing churn charts, creating capitalization policies, etc...

- Deciding what to sell, where to sell it, and how much to sell it for. Tasks here relate to remarketing and disposal of equipment, which includes online ads, auction houses, strategies on local versus global sales, tracking proceeds including gain/loss projections, and other activities that maximize the return on investment.

Operate it

This stage includes:

- Managing risks and complying with legislation or regulations. Tasks relate to compliance and risk management which range from standards for safety such as safe work instructions, PPE plans, and spill or incident response protocols, along with maintaining valid certifications, registrations and insurance coverage.

- Being in the right place at the right time. Tasks here relate to moving the equipment to minimize undeployed time. This requires some form of dispatch or scheduling system, knowing shipping weights, and using proper documentation such as bills of lading and packing slips.

- Generating revenue or income from use. Tasks here relate to operating the equipment as well as conducting pre-use inspections, safety and maintenance checks, operator training and competency programs, etc… Tracking assets. Tasks here relate to determining how much life of the asset is consumed and what it is doing. This relates to knowing the location and status of all pieces, recording meter information, monitoring fuel consumption, calculating availability, reliability, and utilization.

Repair and maintain it

This stage involves:

- How to perform maintenance to reduce unplanned failures. Tasks here relate to some form of preventive maintenance program that specifies the intervals for fluid and filter changes as well as routine services. The purpose of this PM program is to help prevent breakdowns and ensure optimal performance.

- How to assess machine health. Tasks here relate to the singular goal of identifying issues early: Performing routine inspections and monitoring equipment through real-time sensor data. This also includes condition-based monitoring (CBM) programs, oil sampling, non-destructive testing (NDT), and vibration analysis (VA).

- Fixing what broke. Tasks here are focused on repairing equipment and reducing downtime, which includes prioritizing and advancing repair work and managing downtime.

- How to ensure reliability. Tasks here relate to wear or time based activities that are performed to improve asset reliability and efficiency and/or extend the useful life. These tasks range from rebuilding/replacing components to performing major rebuilds or overhauls as well as incorporating technological updates.

Level up

The last stage is arguably the most critical to the longevity of the business as it relates to continuous improvement. It includes:

- Knowing the costs. Tasks are focused on equipment accounting—using internal rates, tagging/tracking expenses to unit numbers, creating budgets and forecasts, generating financial reports, and analyzing variances to ensure equipment costs are not eroding profits.

- Investing in people. Tasks here relate to human capital management, that is, the people who use or make the decisions on the equipments’ behalf. This could include creating/updating job descriptions, onboarding, training programs, employee retention, and succession planning. All activities here are focused on enhancing competency, collaboration, and capability.

- Making things work simpler and smoother. Tasks here relate to automation and integration that enhances the organization’s efficiency and capability, and range from harnessing technology for work orders, computerized maintenance management systems (CMMS), telematics, digital time capture, AI, and any other enhancement that furthers automation and integration. Activities here will vary immensely from organization to organization. For example, one organization may be pursuing digital time capture; another is working on telematics sensor data integration.

- Infrastructure to improve quality and reduce downtime. Tasks here are focused on facilities and tooling as well as employee health and wellness. Examples include specialized tools, hoists, centralized fluid distribution/extraction, service vehicles, and 5S or Kanban initiatives as well as small details like lunch and locker rooms, gym memberships, and education funds.

To effectively navigate the Equipment Cycle, it is essential to recognize the interconnectedness of its four stages. Each stage supports and enhances the others, creating a seamless loop of acquisition, operation, maintenance, and continuous improvement that extends beyond the borders of traditional organizational charts. By fostering a culture of collaboration and clear communication across departments, companies can ensure that every piece of equipment is used to its full potential, thereby maximizing efficiency and profitability.

Understanding the Equipment Cycle is not just about managing machinery; it’s about optimizing the entire operational ecosystem. By viewing the equipment management process through the lens of the Equipment Cycle, fleet managers can ensure that all critical activities are performed, resources are utilized efficiently, and continuous improvements are made. Embracing this holistic approach will transform the way departments and people work together while enabling an equipment-intensive company to operate at peak performance.

About the Author

Craig Gramlich

Craig has extensive experience in equipment management across transportation, heavy lifting, civil projects, mining, and construction sectors. Driven by a passion for cost and data analysis, he excels in enhancing equipment accounting, rate modeling, and developing programs for rate escalation and transfer pricing.

Through Lonewolf Consulting, Craig effectively unites Equipment, Operations, and Accounting departments, leveraging his extensive field experience to help companies streamline operations and find cost savings, significantly boosting ROI.

He holds a Bachelor of Commerce from the University of Alberta and a Certified Equipment Manager (CEM) certification, along with a variety of professional development courses, showcasing his commitment to ongoing professional growth.