Move to Certification Based Compensation to Keep Technicians

The heart of any well-run construction equipment organization begins with machinery that must perform as intended. Talented, trained, and resolute professionals committed to keeping that equipment operating are essential for the organization to be fully operational and productive. For decades, these professional equipment technicians and management teams have been content with establishing long-tenured careers within a specific organization. A new generation of fleet professionals, however, is eager to advance without sharing the same tenure philosophy of prior generations. This creates a significant recruitment and retention challenge.

To field the most productive equipment and positively affect its bottom line, the organization trains its workforce on the latest advancements in technology and best practices, and promotes advanced learning and certifications within necessary and specific competencies.

Want more on asset management?

As we move toward equipment automation and autonomy, organizations should re-evaluate and update their current succession and advancement plans to attract and retain a highly qualified workforce to meet current and future fleet requirements. No equipment fleet is immune to the rapidly advancing technology being deployed within new equipment, and fleets must implement a system to incentivize recruitment and retention of qualified technicians to maintain this technologically sophisticated equipment.

According to the May 2021 U.S. Bureau of Labor Statistics report, approximately 145,000 heavy-equipment technicians were employed within the industry. Vacancies account for another 20,000 equipment technicians, which makes competition for qualified technicians fierce. On top of this need, projected job growth is expected at an annual rate of 6 to 8 percent over the next decade. The report’s annual salary range was $37,290 ($17.93 per hour) to $78,420 ($37.70 per hour) with the median annual wage for heavy equipment mechanics at $58,030 ($27.90 per hour). The same report identifies computer-related career fields competing for the same talent pool as having a salary range from $75,000 to $100,000, a significant increase in compensation above a heavy-equipment technician.

Most organizations address technician compensation with a market value approach, evaluating average salaries from across the nation or a region and using them to develop a specific salary range and compensation package. Included within this compensation package is a base rate, starting with an entry-level position with an ascending scale dependent upon experience-based qualifications and tenure. Most have some type of benefit package as well as some additional compensation—in the form of annual bonuses and commissions, profit sharing, and overtime allocations—that potentially increase the base rate by as much as 20 to 30 percent. Even with this additional compensation, heavy-equipment technicians will earn less than most IT-based peers, and the field is less attractive to the emerging workforce as well.

Recruitment and retention tools include high school and technical school apprenticeships, mentoring programs, and advertisement and outreach on job search websites. Although these efforts continue to produce reasonable results, organizations that operate in-house maintenance operations struggle to fill vacancies. Now is the time to evaluate the benefits of transitioning to an advancement and compensation program based upon technical and managerial certifications.

The emerging workforce has used technology their entire life and are highly adapted to using it to learn and advance their careers. They have the overall mindset of accelerated career advancement, empowerment, and inclusion in the decision processes that define their respective careers. They analyze organizational culture for these attributes as they consider whether to join an organization. They do not make decisions to join solely upon compensation, but given similar organizational cultures, compensation remains the No. 1 factor in the decision to join a specific team.

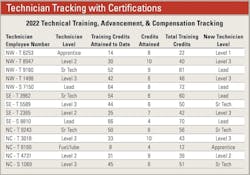

Above: This sample table shows how to track technician advancement using a certification-based model.

Understanding this, transitioning from a tenure-based advancement and compensation program to a certification advancement and compensation program is swiftly becoming a popular tool for organizations to better attract and retain highly qualified technicians and equipment managers.

A certification advancement and compensation program benefits both the organization and the existing and future workforce. To the organization, the plan demonstrates its commitment to the workforce, increasing the potential to attract highly qualified applicants. The potential to increase workforce retention by 10, even 20 percent is a significant decrease in vacant positions to fill. When considering the cost of recruitment, onboarding, and training, such a reduction in cost offsets much of the new program cost. With more stability within the workforce, competency and productivity increases help in meeting tight project timelines and customer satisfaction requirements. Such stability also brings decreased risk: financial, as increased productivity reduces delays and associated costs; and physical, as a stable workforce offers better cohesion and increased safety on project sites.

Benefits to the workforce include increased compensation potential over a reduced tenure, and organizational commitment and investment in employees. It indicates workforce empowerment and inclusion within decisions, which affect their respective career paths.

Establishing a certification compensation program will be unique to each organization, dependent upon the types of equipment within their fleet. Fleets can certify the workforce across all its OEM suppliers. They should also explore and include external training opportunities that often come with a certification program.

Each organization should develop an equivalency schedule for other training and certifications, as there is no standard in place. Some organizations use a college credit system where every eight, 16, or 24 contact hours of training are equivalent to one, two, or three college credits. Top public fleets have developed certification advancement and compensation programs utilizing ASE certifications and other specialized training and certifications.

Any certification must include a minimum of 8 contact hours and pre/post testing to qualify. Post-training testing validates increased knowledge upon the specific subject before certification is awarded. Once the credit system is developed, levels of advancement can be created. A fuel/lube tech would move to apprentice with 20 credits, for example, continuing through the levels to lead technician at 60 points. The above chart provides an example of how to track technician advancement.

Certification compensation must not be solely contingent upon attainment of the certification itself. Prior to any advancement and compensation disbursement, and to maintain workforce accountability, the organization needs to ensure such capabilities exist. Technicians must demonstrate full capability to perform all tasks included within each certification. Only upon successful demonstration should compensation be granted.

Recertification must also be factored into the program. Technology advancements and updates to newer equipment drive changes in most equipment maintenance competencies over a period of three to five years. Technicians and supervision must recertify to maintain their technician status and compensation level. Failure to recertify may cause a technician to descend to a lower, less-compensated level.

Transitioning from a tenure-based program to a certification-based program takes planning, leadership teamwork, and workforce input to be successful. There are costs involved, too, but given the current competition for qualified fleet professionals, the question for each organization should be, “Can we afford not to move in this direction?”

About the Author

Mike Brennan, CEM

Michael Brennan is a 40-plus-year industry veteran and consultant in vehicle and equipment maintenance management. A three-time recipient of the AEMP Fleet Masters Award, he focuses upon process improvement, facilities management, succession planning, technology, and lifecycle analytics as the cornerstone of success in the equipment management industry.

Read Mike's asset management articles.