The equipment manager role is one of the highest profiles and demanding positions within a construction organization. Often regarded by executive management as organizational experts, equipment managers interact with cross-functional teams to support the equipment-related requirements of the organization. They simultaneously collaborate on numerous initiatives, which makes it imperative that they understand specific requirements and core competencies of the various organizational functions to successfully fulfill these equipment requirements.

Equipment managers approach such organizational interaction with an inquiring mindset, keeping their finger on the pulse of the industry as well as the organization. They must review and question other functions’ operational processes to better understand their support requirement needs. They understand the organizational cohesiveness required across the various organizational functions to assist in developing the organization’s vision for the future.

Go to ConstructionEquipment.com/Institute for more on asset management.

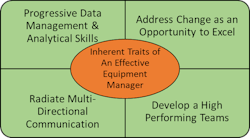

Industry evolution requires a new set of inherent traits for equipment managers. They must have progressive data management and analytical skills as well as the willingness to accept change as an opportunity to excel. They must radiate effective multidirectional communication and have the insight and leadership skills to develop and retain a high-performing team. These are key traits for future success.

Progressive data management and analytical skills enable an equipment manager to keep pace with the industry and maintain cost-effective equipment services. The function of equipment management revolves around an in-depth understanding of the financial aspects of both capital and operational asset funding as well as the intricacies of replacement and maintenance schedules. The rapid advancement of technology deployed across the various types of equipment over the past five years has become an invaluable asset for equipment management effectiveness. This technology supplies a tremendous amount of detailed data captured and transmitted from the equipment, which requires a more detailed yet systematic approach to deciphering available data in order to increase the effectiveness and productivity of the equipment fleet.

How to identify KPIs

Increasingly, equipment managers are required to identify, manage, and supply the data and key performance indicators required by the various levels and functions of the organization. This information provides the actionable data that allows all to better home in on the organization’s strategic plans. Technicians, front line supervisors, and material specialists utilize the data from machines and work orders for effective diagnosis, shop scheduling, and failure analysis. Operations managers utilize operational equipment data (idle hours versus run time, fuel consumption) to measure the effectiveness and efficiency of existing operational processes. Executives may at times review detailed machine operational data, but generally they utilize the financial data metrics (cost per hour broken down by PM, repair, fuel) to track project efficiency and effectiveness.

The equipment manager is responsible to put in place and manage the mechanisms to supply data in real time to support the various functional and organizational objectives. Executives, peers, and staff increasingly rely upon the data-driven recommendations from the equipment manager on how actionable data can be utilized to increase overall organizational effectiveness.

At the core of effective equipment management are processes and procedures that produce a certain desired outcome. Equipment managers rely upon these processes and procedures to maintain at high levels the reliability and predictability of the equipment and the department’s overall operations. Equipment managers, the executive branch, and most people throughout the organization trust in the stability of these processes. If left unchecked in light of industry change, however, these tried-and-true processes and procedures stagnate and could turn the positive outcomes of the past into regression or even negative results.

Equipment managers and those at other levels of the organization have a natural tendency to resist change. Maintaining the status quo tends to be the path of least resistance. They are much more comfortable in their predictions as the reliability of the tried-and-true have been validated previously.

Yet equipment managers must resist the “status quo” mindset and embrace the reality of continuous change. New technologies are being introduced at levels never seen before, rapidly changing the industrial landscape and business environment. Equipment operators, technicians, and support staff entering the workforce today have a technical mindset and are well versed at applying such technologies to increase the effectiveness of their performance.

Such rapid change requires equipment managers to look at processes and procedures with a different perspective. They must embrace change as an opportunity to excel. Through research, detailed data analysis, continuous learning, curiosity, and willingness to manage the risk of change, equipment managers must develop and refine new processes and procedures designed to evolve over time with technology and the changing landscape of the industry.

Equipment managers communicate with technical and support staff, operational managers, peers across the organization, and the executive branch, as well as with external vendors and other partnering organizations. Through open communication, they maintain pace with the organization’s operational objectives. They ensure the equipment requirements are met and coordinate with vendors and partners on any changes in schedules to maximize efficiency and solve any deficiencies in processes.

How to communicate across the organization

Equipment managers must radiate multidirectional communication across all staff and managerial levels as technology advances and the tempo of operations increases. Within the equipment function, they must instill and promote such multidirectional lines of communication that allow data and information to flow from top to bottom almost instantly. In doing so, technicians, back office, field, and support staff will have a greater understanding of changing objectives, maintenance schedules, and other pertinent information. Simultaneously, fulfillment and the performance of schedules, objectives, and fleet-availability information is available to equipment and operational managers in almost real time. Organizationally, developing such multidirectional communication across the various functions and the executive branch fosters increased collaboration and effectiveness of specific projects and overall organizational objectives.

To remain competitive, an organization must instill multidirectional communication so that equipment and operational data flow across all functions to ensure schedule management and project timeliness. The most valuable resource within any organization is its human resource. Without a team of highly qualified and engaged individuals, keeping pace with the evolution of the industry will be an almost impossible task. Equipment managers have for years struggled to attract, hire, and retain a qualified workforce. Many have created internships, supported and promoted their organization in vocational and trade schools, and even addressed career opportunities at the high school and middle school levels in hopes to increase the talent pool available. Many maintain open-ended employment opportunity postings in their efforts to have enough hands on deck.

The current and future workforce is rarely satisfied with a static 8-to-10-hours-per-day position. Although increased compensation can help, they require inclusiveness in a team-oriented setting with opportunity for internal advancement. They require performance-based compensation packages, flexible work schedules where available, regularly scheduled training, increased responsibility, and accountability for both team and individual performance outcomes. They want to be treated as a vital member of the team, having their views and recommendations considered with respect. Most importantly, they want to enjoy the work they perform.

The challenge for equipment managers for the foreseeable future is finding, attracting, and retaining such individuals to develop and advance as a highly effective and performing team. They must make it a priority to initiate and promote a career development program that includes the personal development, responsibility, accountability, and recognitions required by the workforce of today and tomorrow.