I have, for a number of years, been proposing an economic life or sweet spot calculator based on knowing the equation of the cumulative cost curve. Many managers have successfully used it; others are confused by the concept of cumulative cost and have stayed with their current methodologies.

Although cumulative cost works, cost per hour life to date (LTD) is the gold standard when it comes to analyzing equipment cost. Here, then, is a methodology for using LTD hourly owning and operating costs to calculate the sweet spot. We’ll use some data from a fleet of haul trucks to see how it works.

Cost per hour Data |

|||

| Unit | Hours worked LTD | Repair Cost LTD | LTD repair cost/hr |

| 1 | 2,767 | $32,201 | $11.64 |

| 1 | 5,686 | $127,353 |

$22.40 |

| 1 | 9,368 | $281,191 | $30.02 |

| 1 | 12,628 | $432,264 | $34.24 |

| 2 | 2,781 | $41,450 | $14.90 |

| 2 | 12,995 | $261,075 | $20.09 |

| 3 | 2,784 | $37,380 | $13.43 |

| 3 | 6,064 | $153,692 | $25.34 |

| 3 | 9,728 | $285,737 | $29.37 |

| 3 | 12,754 | $400,851 | $31.43 |

| 4 | 2,495 | $50,702 | $20.33 |

| 4 | 5,653 | $149,577 | $26.46 |

| 4 | 9,397 | $244,152 | $25.98 |

First, collect and plot the data. The unit number, hours worked life to date (LTD), and repair cost LTD data are given in the first three columns of the table below for four of the trucks used in this illustrative example. Several points in the life of each truck were recorded to provide 32 data points.

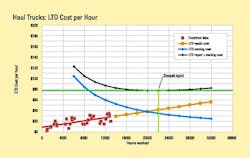

The fourth column of table was calculated by dividing repair costs LTD by hours worked LTD to give LTD repair cost per hour at those same 32 points in the life of the trucks. The 32 data values were plotted on the accompanying graph (the dark red data points in the bottom left of the graph). None of the units is more than 14,000 hours old, and they are running with LTD repair costs of about $20 per hour with a clear and strong upward trend.

The next step is to understand this trend. You can add a trend line by eye and estimate the initial value (where it crosses the vertical axis) and the slope. You can also use Excel to add a linear trend line and calculate the initial value and slope. This method provides an initial value of $9 per hour and a slope of $1.50 per hour.

The initial value and the slope is “the voice of the data.” It tells us that the LTD repair cost per hour is $9 when the trucks are young and that this grows by $1.50 per hour for each 1,000 hours that the trucks work (the dark red line). This means that at 12,000 hours we can expect the LTD repair cost per hour to have reached $27 per hour ($9 + (12 x $1.50)). Growth should continue until we get into a steady state of component replacement.

The final step is to use the knowledge we have gained from the data to analyze a typical haul truck that exhibits the characteristics of the units in our fleet.

First, we set up an analysis table and enter in the first column the hours we assume the machine will work. In the second column, we estimate the likely residual market value for various points in its life cycle. Based on a $930,000 purchase price, we use a standard downward sloping decay formula. The third column gives a simple LTD hourly owning cost by dividing purchase price minus residual market value by LTD hours. Although we can come up with a more complex calculation, these are the big numbers that affect the sweet spot calculation. The values in column three are plotted on the graph as the blue line that gives the downward sloping LTD hourly owning cost curve.

Next we estimate the LTD hourly repair cost for the haul truck, using the initial value and slope for the LTD repair cost per hour. The results are shown in the fourth column, with the first four rows shaded red because they are in the past. Note the $27 per hour “voice of the data” number in the 12,000-hour row. The rest of the numbers in the fourth column are a linear extrapolation of the data using the previously determined initial value and slope. The values in column four are used to plot the orange LTD repair cost line on the graph that slopes upward at $1.50 per hour for each 1,000 hours.

The values in the un-shaded portion of column four and the resulting orange line are predictions based on exactly what the data tell us about the past. The values in the column and the slope of the orange line can be decreased or increased if there is reason to believe that the future will be better or worse than the past.

Column five is the sum of columns three and four and is used to plot the black LTD Repair + Owning cost curve. The curve defines a sweet spot life of 22,000 hours at a minimum LTD cost of a little over $77 per hour. This is the economic life for these haul trucks and the foundation for a rate calculation that recognized the irrefutable relationship between age and cost.

The graph provides the following insights about our haul trucks. First, there is no need to think about replacement at this time; the sweet spot is well in the future. Second, if things stay as they are, the sweet spot is likely to be 22,000 hours at a LTD cost of $77 per hour for the cost types included in the analysis. Third, our analysis is based on the assumption that repair costs will grow at $1.50 per hour for each 1,000 increase in age. Any steps to lower this rate of growth will increase the economic life and significantly reduce the rate. Most important, the graph explicitly shows how we have used the data to forecast the future. An estimate of a 22,000-hour economic life based on 12,000 hours of hard data is a bit of a long shot, but it is the best we can do at this time. A year from now, we will have more data, be closer to the sweet spot, and be in a position to make better quality predictions.

Congratulations to Mike Vorster for winning the National Gold AZBEE Award for editorial excellence for Equipment Executive.