Service facilities represent a major fixed overhead expense for fleet managers. For some, it's an expense they would eliminate if a distributor/independent service provider could perform to their standards. For others, it's an integral part of the fleet setup.

In both instances, having the right facilities for the fleet means providing efficient, economical and effective service. Fifteen years ago, Construction Equipment first asked fleet managers to describe their maintenance facilities in an effort to benchmark facilities by fleet size, measured in fleet replacement value. On this and following pages, we'll update those benchmarks.

Indoor square footage for maintenance shops averages a bit more than 18,000 square feet for the industry, with the smaller fleets around 4,000 square feet and the larger fleets about 54,000 square feet.

Of course, these are averages. Individual shops will vary in size and by the types of work done in them. But for fleet managers, these numbers provide a benchmark from which to judge their shops with others.

For our research, we were able to garner detailed responses from more than 700 equipment managers of all sizes of fleets. On this page are basic stats on how service facilities measure up. Turn to the subsequent pages for a more detailed look at facilities by fleet replacement size.

Benchmarks for Fleets: Less Than $500,000

Space for the storage of parts and machines is common with small fleets. Most don't, however, see the value of space devoted solely to painting.

Benchmarks for Fleets: $500,000 to $1 Million

Component rebuilds are at a level slightly higher than that for the smallest fleets, with engines and hydraulic brakes still at the top of the list.

Benchmarks for Fleets: $1 Million to $5 Million

The percent of fleets who tackle rebuilds of differentials and final drives jumps at this size range. Engines and brakes continue to lead the list.

Benchmarks for Fleets: $5 Million to $10 Million

Benchmarks for Fleets: More Than $10 Million

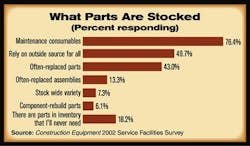

Fleets won't take chances on being out of consumables or common parts. Managing that inventory becomes harder, as four of 10 say they have unnecessary parts on hand.