Technology fuels family contractor growth

One of the things DJ Rutledge, VP of Rutledge Excavating, based in Equinunk, Pennsylvania, is most proud of is how the family-owned company has grown from a few employees, an excavator, and a dump truck in 2010 to the firm it is today, with 45 employees and a host of contracts under its belt from the state DOT and DNR for earthwork, as well as conservation work from the National Park Service.

It also does FHWA work and a variety of site preparation jobs.

Today, the fleet includes six tri-axle dump trucks, 14 excavators, four GPS-integrated dozers, ADTs, motor graders, and more.

“We have our own mobile material crushing equipment for our bluestone quarry, plus if we have enough use for it, we bring those out onto job sites,” Rutledge says. “We crush quite a bit of our own material on sites to use. We have just a little bit of little bit of everything. We’ve got wheel loaders, big and small, skid steers, and even road pavers for newer asphalt and our walking trails. We do quite a few walking trails.”

Rutledge Excavating’s growth has been achieved through hard work and nurturing a team atmosphere. Every employee pitches in across disciplines when necessary, and there are several who have been with the company since the beginning.

“Nobody is better or less than somebody else,” Rutledge says. “Everybody’s equal. Doesn’t matter what your job title is. If you see somebody that needs help, we’re all a team. I wouldn’t ask anybody to do what I wouldn’t do.”

How technology fuels company growth

The company also embraces the latest technologies to help it grow, including machine control and drone mapping.

Both technologies were on display at the company’s Epsy Run stream bank project in Wilkes-Barre, Pennsylvania. Rutledge is tasked with transforming drainage on a mountainside, removing earth and timber work that is 70 to 80 years old.

“There is an old stone-laid reservoir, and years ago they had filled in the valley and erected two underground channels that have wooden ties, and basically over the years that had become dilapidated due to age,” Rutledge says. “The scheme of this project is to bulk excavate out and to construct a new [above ground] stream channel, and then at the end of the tie-in, the project is to dewater and take down the existing reservoir and allow it to naturally flow on its own.”

Rutledge is using a Komatsu D61PXi intelligent dozer for grading. Two excavators are at the site; one is carving rock out of the mountainside for lining the new stream bed and the other, a Caterpillar 336F Hybrid, was arranging the rock and hammering the larger pieces down to size.

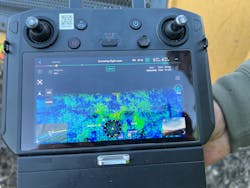

They are also using their own 16-pound DJI drone on the project.

Corey Rutledge, project superintendent for the company and DJ’s cousin, is the drone pilot and the technology guru for the company.

“I love to learn, and technology is something that has pushed our business forward,” Rutledge says. “We like to push the limits to make ourselves as efficient as possible. It always comes at [an initial] cost, but it all pays off in the end. With GPS, the survey equipment, the top iPhones, as well as the DJI LiDAR drone, we're able to be as efficient as possible and produce the best information for our clients.”

The day’s drone flight at the Epsy site was a progress flight, according to Corey. He explains the process.

“At the beginning of each project before we put a bucket on the ground, we will take a flight over the site,” Rutledge says. “That creates an existing conditions map that can be compared to the plans given during and through the contract from the engineer.

“Today, we've excavated for a month, and it's the end of the month, so we need to justify our payment quantities,” Rutledge says. “By doing a flight today, we can compare how much earthwork we've moved and where we've moved it, whether it'd be off site, or in this case, we hauled it to another location on site. You can verify it two ways.”

Benefits of drones for earthmoving

The drone flew the 35-acre site in six minutes, according to Corey Rutledge, with about five minutes of actual data collection.

“It took 110 still photos, which will be used for the photogrammetry,” Rutledge says. “With photogrammetry, we're able to see the site and it creates one large picture. Then we use the LiDAR, which gives us gives us very high precision and all the millions and millions of points. It will weed out the trees, equipment, and vehicles that might mess up our data and leave us with ground points that wouldn't help create our surface.”

LiDAR also penetrates through heavy tree cover. “There's a precision that is out of this world,” Rutledge says. “We can pull up to a wooded site and not have to cut a single tree to do a survey and tell exactly what the elevations are on the ground, find the holes, find out where the water is currently running, and go from there. You can’t beat a drone with boots on the ground doing traditional surveying.”

In addition to verifying progress and payment, plans are fed into the crawler dozer for execution. It all adds up to increased efficiency and time and cost savings.

“The way my father grew up, everything used to be stringline and grade stakes, and having the surveyor come out,” DJ Rutledge says. “For us, it just made more sense to be self-sufficient. On a bigger site job like this, it eliminates all labor putting in the grade stakes with a surveyor and then having multiple layouts.

“With integrated [grade control] machines coming out, it just made more sense,” Rutledge says. “Everything's right there—that operator can just go. Everything is right in front of his eyes, right in the machine with him. There are so many opportunities, so many things you can do with the GPS and the new LiDAR drone we've got. It saves so much time and it's more accurate.

“To calculate how many cubic yards of material you moved, how much more needs to be moved, or how much we’re over quantity, it's just opened it up a whole new ballgame,” Rutledge says. “It’s one of those things that you kind of scoff at off at first when you think about it, but it’s the new way of the world and the way things are going.”

Talking to the Rutledges, one gets the feeling that the work is the easy part. The hard part, particularly now, is attracting and retaining people to do the work.

“Let’s face it, it’s very hard to find people who want to do physical labor, especially being out in the elements in the weather up here,” Rutledge says. “There's lots of great knowledge and people out there, but a lot of them are retiring.

“I graduated [high school] in 2011 and it was pounded into us then in school that you need to have a college education and you need to pursue that,” Rutledge says. “In this field, what we’re doing, the best way to learn is by doing it. I'm a firm believer in that. That's the way I learned. Every day is a new day to learn something; it doesn't matter how old you are or how much experience you’ve got, there's always something new to learn and somebody to learn it from.”

Building a work force

He feels a college degree isn’t necessary to earn a good wage, pointing out that 99 percent of the work Rutledge excavating does is prevailing wage. Construction firms are paying and work is abundant.

“You try to keep everybody, do the best you can, and treat everybody with the utmost respect and like family,” Rutledge says. “That's what we are. We're a family-owned and -operated company. We have a fantastic group of individuals that makes this company what it is, because it doesn't matter who the president is, every single person has a role.”

On the Epsy job, Rutledge jumped in with a pile of shop rags to wipe off hydraulic line couplings when he saw a crew changing excavator attachments.

“Our No. 1 motto is if you if you want to take on responsibility, and that doesn't need to be running a full-blown job, if you want to take charge of a simple task like preparing subgrade for a parking lot, or doing the tension basin, we will never hesitate or hold back anybody,” Rutledge says. “If you show us that you want to learn and grow, that's what we all want to be, leaders in the end. But it’s very tough to find young people that want to step up to the plate and take that initiative.”

Rutledge Excavating does most of its own maintenance but does not have a set-in-stone acquisition and disposal policy. They target 10,000 hours of life for most machines, but good actors may be kept longer. The bad actors will be dumped.

When the time comes, Rutledge handles disposal through Ritchie Bros. Auctioneers or sells privately. “We auction some off and sell some privately because the equipment right now is phenomenal to sell,” he says. “I’d [rate it] not so good to buy or horrible to buy.”

His 336F Hybrid is a piece Rutledge bought slightly used but still under warranty, and it’s one of the outliers on hours.

“The 336 hands-down is tremendous power-wise, and the fuel consumption is very good for that size of the machine,” Rutledge says. “That, for instance, is one of those ones that we can’t retire because it's been such a tremendous machine with 11,000 hours on it as of today.”

Though he has embraced the hybrid excavator, he’s not likely to go electric with any equipment, even though he does environmental work that involves conservation and restoring land.

“If you look at the grand scheme of things, look at what it costs to make that battery and all the emissions in the process of making the batteries, and then what happens if for some reason they go out? We’re out of power,” Rutledge says.

“We could have a power grid meltdown, or we could run out of the materials to make batteries,” he says. “I would never trust a battery-operated excavator if you're working in a stream or a real critical area, or even a dump truck for that matter, or a semi-truck going down the highway. There are just too many factors.”