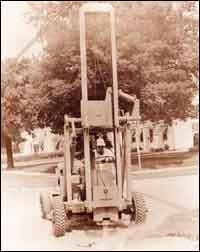

This early-production A30 was one of the mobile hydraulic drop hammers produced by Arrow, which launched the machine in 1955.

Some machine innovations enjoy instant success and bring great financial rewards for their inventors. Others are ahead of their time and rapidly fade from the scene through lack of promotion or the unwillingness of customers to change traditional habits.

The Arrow hydraulic hammer fits into neither of those extreme categories. The limelight never shone on this machine, and it was never exactly a household word. Yet it has survived for almost half a century, little changed from its original design, and is still hitting hard in its niche market of scoring, cutting, breaking and tamping.

The Arrow Manufacturing Co. was founded in 1943, in Denver, and produced a variety of equipment for the construction industry. In 1955, the Arrow mobile hydraulic drop hammer was introduced. This versatile self-propelled vehicle carried a hydraulically driven hammer mounted in a moveable frame. The frame could be angled or moved from side to side across the width of the machine for working close to walls or other obstructions. The operator could set the machine for manual or automatic operation. In automatic mode, he could select the height of hammer drop and speed of travel to deliver blows of uniform impact at a uniform rate. The patented hydraulically powered "creeper gear" provided working speeds up to 32 feet per minute. With the hammer frame folded down, the machine could be driven from job to job at speeds up to 30 mph.

Sales of the hammer grew worldwide and, over time, the Arrow became the industry standard for breaking concrete, compacting trench backfill, and cutting asphalt. The machine's versatility attracted the attention of Lemand Machinery in the United Kingdom, and they began assembling the machine under license in 1963 with a British diesel engine. In 1969, Arrow C.E. Ltd, England, was granted the rights of manufacture and sales of the Arrow Hammer in Europe.

In 1975, East Moline Metal Products, a contract manufacturer based in East Moline, Ill., acquired the assets of Arrow Manufacturing Co. and moved the operation to its Moline facility, where production of the Arrow Hammer resumed. The Arrow Hammer business was conducted through EMMPCO, a wholly owned subsidiary company of East Moline Metal Products Co., until 1989 when operations were absorbed by Arrow-Master Inc. The Arrow Hammer remains a viable part of the Arrow-Master product mix to this day.

Although its basic concept and applications remain unchanged, the current Arrow Hammer, Model 1350, has seen more than a dozen model changes since its inception in the mid-1950s. Still used by utility companies; state, county, and local municipalities; and all classes of contractors; the Arrow Hammer has survived strong competition from a wide field of hammer products introduced over the years. Its lasting popularity and longevity is a testament to its unmatched combination of high production and versatility.

You can read more about the evolution of construction equipment in Keith Haddock's illustrated book "The Earthmover Encyclopedia" available in most book stores. Also, consider a membership in the Historical Construction Equipment Association at www.hcea.net.