Four Ways Asset Management Software is Critical to Project Success

Management of an organization’s construction equipment fleet helps to ensure that projects are completed on time and within budget. In addition to keeping track of equipment, asset management can also include resources, materials, and personnel and can help construction managers to plan, monitor, and control projects more efficiently.

Efficient project management is essential for achieving a successful outcome in the construction industry. Asset management is one of the most effective ways to improve project efficiency by enabling project teams to track, monitor, and control their assets throughout the construction process. This ensures that resources are utilized to their full potential and eliminates unnecessary waste.

Hayden Price is the Technical Product Manager for HCSS Equipment360.

Asset management also provides visibility into the condition of each asset, allowing for preventive maintenance to be scheduled when needed. By ensuring that machinery and equipment are adequately maintained, costly repairs and downtime can be avoided. Furthermore, preventive maintenance helps extend each asset’s life cycle, further improving project efficiency and reducing costs.

Four key asset management processes

1. Track and manage assets

Equipment assets make a project possible. Managed properly, they help avoid problems that can delay the project timeline and add extra costs. This makes asset management one of the most critical aspects of successful project management in construction.

An effective asset management system ensures that all resources needed for a successful completion of the project are in place before it starts and that they remain in good condition throughout its duration. Project equipment needs to be tracked to ensure it is used where it is supposed to be by the right team member. Equipment can go missing on a construction site due to theft or an unauthorized person using the equipment scheduled for a particular job.

By tracking and managing assets effectively, construction teams can also guarantee that all necessary materials are available when needed. This can eliminate unnecessary delays due to material shortages or unavailability and reduce costly reordering fees or additional labor costs associated with having to wait for materials.

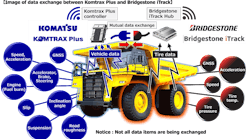

Tracking the location and status of high-dollar assets throughout a project is essential. The size, value, and usage of these assets make them essential to manage. Investing in good tracking systems can help you identify where assets are located on the job site and their condition at any given moment. Equipment can be outfitted with electronic sensors, telematics equipment, or GPS devices to track location.

2. Monitor equipment performance and preventive maintenance

To keep equipment running at peak performance, it must be maintained properly and regularly. Regular preventive maintenance on construction equipment enables asset managers to identify potential risks before they become significant issues. As such, preventive maintenance helps reduce delays and potential safety hazards caused by unexpected equipment failures.

Preventive maintenance ensures that any problems with machinery and other assets are identified early on before they have the chance to cause significant damage or downtime. Preventive maintenance can save companies significant money in the long run, as it helps avoid costly repairs and replacements.

Regularly servicing assets, can reduce wear and tear, prolong their life, improve efficiency, prevent unnecessary breakdowns, reduce energy costs, reduce accidents, and keep operations running smoothly.

Preventive maintenance can increase the lifespan of a construction asset since it allows manager to identify and replace any worn or damaged parts before they cause severe damage. It also helps to extend the life of expensive machinery and reduce unexpected downtime due to malfunctioning equipment. All these advantages provided by preventive maintenance highlight how essential asset management is for the success of any construction project.

Preventive maintenance can provide invaluable data about how different assets perform over time and inform decisions about future investments or upgrades. Although preventive maintenance is a cost to be borne, it ultimately pays off in the long term to keep assets running efficiently.

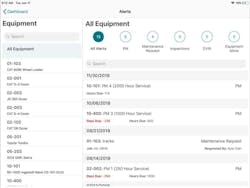

Using technology to stay on time with a preventive maintenance schedule is vital for keeping equipment at top performance. Software with alerts set by calendar days, run-time hours, and equipment odometer makes it easy for technicians to enter work order information. Technicians can also see what is needed to be done to that machine before they start the repair and have the proper tools on hand, whether in the shop or in the field. Projects can be delayed if a technician must run back and forth to the shop to repair a piece of equipment out in the field.

Heavy equipment maintenance software allows project managers to submit, review, approve, and reject timecards. This software can integrate with the accounting system to eliminate double data entries, making payroll easier.

3. Monitor spending on assets

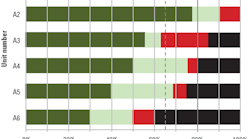

One of the most critical aspects of asset management is its ability to keep project costs in check. Through effective asset tracking and management, construction companies can keep a close eye on their assets and ensure that they are being used to their full potential. This helps ensure that assets do not sit idle or underutilized, reducing operational costs.

Keeping track of spending on asset management will help stay within budget and avoid unexpected costs arising from repairs or replacements. With asset management technology, maintenance and repair charges can be input to cost codes and damages assigned to specific jobs. This feature also helps plan preventive maintenance tasks, which helps reduce the number of expensive repairs later.

From the data collected on assets, management can track the lifespan of the equipment and proactively plan for when new assets are needed. Equipment is only available for a limited amount of time before it needs replacing. The lifespan of equipment, however, depends on how the equipment is used and treated.

4. Documentation and inspections

Documenting inspection records helps maintain asset performance, reduce costs, and plan for future needs. Documenting all assets within a project can help with accurate reporting, providing details of the condition and value of the assets and making it easier to track their movements. Technology can help keep track of appropriate documents on each piece of equipment by creating a digital record of inspections and maintenance. By keeping records of all equipment inspections and maintenance, management can track changes in asset performance and better identify any potential issues before they become a problem.

Regular inspections are essential to identify potential issues, and preventive maintenance is key to preventing them. A detailed record of all inspections and maintenance operations can help ensure that all assets are performing as expected.

By keeping detailed records of asset inspections and maintenance operations, management can also plan for future needs. This will allow them to manage costs effectively, budget for future expenses, and proactively identify and address potential problems. Documenting inspection records can also help optimize asset lifecycles and improve cost efficiency in the long term.

Asset management is vital to keep construction projects running smoothly, efficiently, and at peak performance. If an asset breaks down, job productivity is lost, which means the project may not meet its timeline. Any time an expensive piece of equipment breaks down, downtime and process inefficiencies can decrease bottom-line profits.