When A Wheel Loader Makes More Sense than a Skid Steer

Being on the fence about a small wheel loader versus a skid steer is “an argument traditional skid steer and CTL owners should be having, but they aren’t,” says John Dotto, product application and training specialist with Wacker Neuson. “It’s not to say that a small wheel loader is always a suitable alternative for a skiddy, but if you stop and think about it, small wheel loaders make a compelling argument in a lot of cases.”

The decision must account for not only the requirements of the job at hand, but also the characteristics desired for long-term work with the machine. And there are a fair amount of differences in the categories according to OEMs—even those who make and sell two, or all three, machines.

Compact wheel loaders offer more

“There is a place for [each of them] on the job site,” says Hitachi’s regional business manager Dustin Hoogeveen. “But in specific instances, one will perform much better than the other. Both tool-carrier types are versatile because of the variety of attachments they can be outfitted with; however, a compact wheel loader is a more productive machine to use for many applications.

“Compact wheel loaders have more tipping load and more reach to allow for easier loading into a truck or hopper,” Hoogeveen says. “They also travel faster, provide better visibility, and provide superior operator comfort than skid steers. This makes load-and-carry-type operations much more practical for a compact loader.”

Hoogeveen also cites fuel efficiency and lifespan, something important to cost-conscious managers.

“Compact wheel loaders are typically more fuel-efficient to operate,” he says. “Skid steers demand higher horsepower for steering and generating higher volumes of auxiliary hydraulic flow, resulting in most being operated at full throttle most of the time. [Compact wheel loaders’] articulation doesn’t demand a lot of power, and the engine is revved only when the throttle is used.”

A small wheel loader’s useful life is much greater than that of a skid steer, according to Hoogeveen. “A compact loader can run for 6,000 to 8,000 hours in most applications. Most skid steers are used for only about 5,000 hours before they are retired.”

There is also the advantage in tire life, due to small wheel loaders’ steering systems. “Skidding the tires is much tougher on tires than the smooth steering of an articulated loader,” Hoogeveen says.

In addition, there is no need for track maintenance and replacement, as is in play with a CTL.

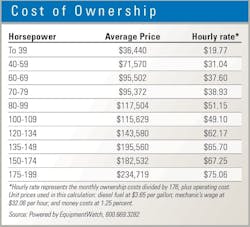

Although the initial purchase price is lower for a skid steer and many CTLs compared to small wheel loaders, Hoogeveen stresses that when each machine type’s cost-per-hour of useful life is compared, the compact wheel loader’s price is “very competitive.”

Going beyond wear and performance stats, managers should consider items like stability, cab comfort and visibility. “The first thing an operator will notice about the difference between a wheel loader and a skid-steer-type [machine] is the stability,” says Nathan Repp, Komatsu product marketing manager, wheel loaders.

“Wheel loaders offer a sure-footed platform for moving materials and handling difficult loads,” Repp says. “Turning is done by changing the angle between the axles, instead of braking or skidding one side of the vehicle and relying on the tires’ traction to the ground.”

Wheel loader breakout force

Wheel loaders typically have higher breakout forces and lift capacities to go along with the increased stability.

“Another aspect that wheel loaders are better equipped with is in the visibility for the operator, where they don’t have the lift arms blocking side visibility and also have a better view rearward, and of all surroundings,” Repp says. “Cab comfort and accessibility are also key. Operators don’t have to climb over work equipment to access the operator station.”

Staying at the front of the machine, attachment use is another area where OEMs give small wheel loaders the advantage. “Wheel loaders...have increased capability to run attachments with hydraulic systems that have dedicated pumps and auxiliary circuits,” Repp says. “When changing attachments with a quick coupler, the types of attachments can have extremely different sizes and weights, which a wheel loader can better account for with increased footprint stability and counterweight placement.”

Volvo Construction Equipment’s product manager for compact equipment, Darren Ashton, says contractors may primarily associate compact wheel loaders with buckets and forks—but they can also be designed to handle more robust attachments. “A contractor should also look for an OEM like Volvo that can factory-fit wheel loaders with extra hydraulic lines for attachments like brooms, grapples, and snowblowers. And for applications like sweeping streets or moving snow, the added height of the cab and increased speed options allow for quicker, easier work compared to CTLs or skid steers,” Ashton says.

Lee Padgett, product manager for Takeuchi, points to automation features as giving small wheel loaders an edge.

“Automation features are helping wheel loaders and their operators achieve more in less time,” Padgett says. “Features like boom height kickout, return-to-dig, automatic bucket positioning, and boom height kickout can really improve efficiency and performance, and these features are not traditionally found on CTLs or skid steers.”

Padgett also references travel speed. “For road construction and maintenance, compact wheel loaders can have a distinct advantage over CTLs and skid steers in many different situations due to their faster travel speeds. Those faster speeds mean wheel loaders can quickly travel longer distances, which can save a lot of time on a road construction project,” Padgett says. “That time savings can be especially important when trying to meet pre-established deadlines for completion. Additionally, high-speed road gear will increase the wheel loader’s fuel economy by keeping the engine rpm lower at higher speeds, saving on fuel costs.”

Managers should also consider production quantities.

“Smaller wheel loaders with 2- or 2.5-cubic-yard buckets can lift and load more material than a skid steer or compact track loader,” says Doosan product and dealer marketing manager Aaron Kleingartner. “Also, the operator can change from a bucket to a pallet fork to lift and carry building materials. These materials may weigh more than an skid steer or CTL can carry.

“It’s also worth noting that some small wheel loaders have a high-lift option, meaning that they may be able to lift and dump materials higher than a skid steer or compact track loader can reach,” Kleingartner says. Transportation is important as well, including how frequently a contractor needs to move a machine.

“For instance, if a contractor is working on a site preparation project that will last for several months, a wheel loader may provide more productivity than a smaller skid steer or compact track loader,” Kleingartner says. “Vice versa, if it’s a shorter job or if a contractor regularly moves machines from job site to job site, a skid steer or compact track loader may be more economical from a transportation standpoint.”

The basics of transport to the job site, regardless of the time spent on site or the site’s expanse, also need to be factored into any decision. “The contractor looking at a small wheel loader as an alternative to a skid steer also needs to take transportation and storage of the machine into consideration due to the physical size difference between the two machine types,” Wacker’s Dotto says. “If any additional trailers [are needed], or trailer modifications need to be made, and if the machine can be stored and worked on in an existing space, all of these are considerations. If your business infrastructure is built to support a wheel loader, the argument becomes much easier to make.”