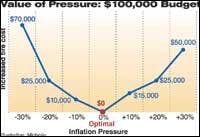

The most important part of a tire is the air, but keeping the proper inflation pressure in every tire is still probably the toughest challenge in maintaining a fleet of wheeled vehicles. Very few do it well, and it's expensive. If your pressures are 20 percent off (for example, running 28 psi in a tire that should be at 35 psi), your annual tire costs will be 25 percent higher than normal.

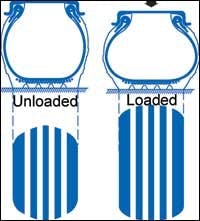

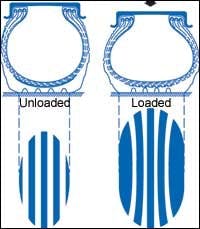

The sidewalls and tread in an underinflated, or overloaded, tire flex too much where they meet the road. The sidewall is constantly flexing and relaxing as it rolls, which generates heat—just like repeatedly bending a paper clip back and forth will heat the wire. Even if the tire's steel belts or plies don't break, the heat weakens the rubber. The closer the casing comes to 270F (rubber's vulcanizing temperature), the more susceptible the tire is to puncture.

Stresses that the tire would easily withstand at normal temperatures—impacts and even braking and cornering stress—can cause a badly overheated tire to fly apart at the seams. That's why the tire industry says a tire should be considered flat if it is run at less than 80 percent of its proper inflation pressure. It should be demounted from its rim and inspected by a trained tire technician to decide if it can be returned to service.

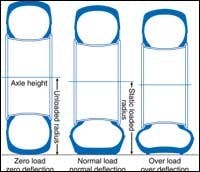

Finding the right inflation pressure begins with finding the right tires for the loads they will carry and the length and speed of the haul. Tire manufacturers calculate the capacity of their products in ton-miles per hour (TMPH). Equipment manufacturers will recommend tires for their machines, but to fine-tune tire costs, you and your tire dealer should calculate TMPH for your typical work.

You start with the average tire load. That's the load on the tire when the vehicle is empty, plus the actual load on the tire when the vehicle is loaded, divided by two. Multiply average tire load times the average speed for the shift. Average speed is the round-trip haul distance times the number of trips per shift, divided by the working hours in a shift. The result is TMPH for the job.

When it comes to tire pressure, less is better. Lower pressures offer better flotation and traction, and because the casing remains more flexible, it resists puncture better. But lower pressures generally cannot handle high loads.

A vehicle manufacturer's rated load seldom resembles actual vehicle loads. When manufacturers recommend a given wheel loader to load a given haul truck with a mixture of clay and gravel in four passes at a given heaped bucket capacity, that's theory. In the real world if the material is wet, for example, it can weigh up to 20 percent more than when it's dry. After a heavy rain, do you put only three passes in the truck or load the buckets only 80 percent full? Not likely.

With sideboards, tailgates, bigger buckets, wear plates, bed liners, auxiliary fuel tanks, and a host of other possible field modifications; tire manufacturers assume that you overload your vehicles until they see proof to the contrary.

If you're serious about lowering tire costs, you need to know the actual load on each axle to make sure the tires are up to the task. Run loaded vehicles over a scale. You may be able to adjust inflation pressure to make the standard tires last longer.

The best solution to overloading is probably to use bigger equipment. But if upgrading machines is a pipe dream, make sure you upgrade tires to match the actual loads.

Match the TMPH of the project to a tire with the same or greater TMPH, make sure the tread pattern will deliver the traction you need, and you've found the right tire for the job.

From this point, selecting the proper inflation pressure is relatively simple. Check out the load and inflation pressure tables in the tire manufacturer's manual. Tire manufacturers are probably better sources for pressure information than general industry tables. For example, Cat expanded the inflation-pressure charts in the 2002 edition of its Performance Handbook to show the tire manufacturers' diverging recommendations for similar tires.

Once you've decided on the proper air pressure, maintaining that pressure becomes a constant chore because air inevitably finds its way out of tires. On machines in daily use, check air pressure every day before the tires warm up. It can take 12 to 24 hours for a large off-road tire to cool down completely, and if long operating hours prevent a daily cold check, gauge the tires hot every day. Don't adjust hot pressure to match the cold-pressure recommendation, though. Simply compare each day's reading to the previous day's to confirm that tires are not losing pressure.

Support hot pressure checks with a cold check weekly, or as often as possible.

Tires on vehicles with less-demanding work schedules can probably be maintained properly with a cold-inflation check each week.

Tire costs will tell you if inflation pressures are properly maintained. Assuming you're starting with the right pressure for the job, high tire costs are probably caused by poor pressure maintenance. If you can't convince your own people to monitor pressures, consider how much you might save by hiring a vendor to manage tires. Even if the contract is more expensive than the tire savings, reducing flat-related downtime on projects may be well worth the investment.