Onboard sensors and wireless data transmission technologies (telematics) have been used to measure machine health and performance since the early 1980s. Development in these areas has led to a plethora of technologies designed to provide fleet asset managers with information on their equipment and to help coach operators.

For more asset management, go to Construction Equipment Executive Institute.

Many systems are relatively simple and provide little more than GPS location and one or two sensor readings. Others are complex, factory-installed systems that provide sensor data drawn from the engine control module and any number of mechanical components. Regardless of complexity, all systems use onboard sensors to measure a particular condition and use algorithms to draw inference from the sensor readings and identify a given sensor status for the machine.

The sensors and, particularly, the algorithms used are very often proprietary and vary by supplier, manufacturer, and in some cases, by machine type. There is no consistency and no agreement as to which sensor or sensors should be used, and there is no agreement on the algorithms used to draw inference from sensor readings and record the machine’s sensor status.

How sensors can define machine status

There is, however, some agreement that sensors and algorithms can be used to define the sensor status of a machine as:

- Not Idle, frequently inferred from sensors that show the machine to be in gear or moving with high engine rpm and/or an engaged implement circuit,

- Idle, frequently inferred from sensors that show the machine to be powered up but not in gear, not moving, and/or with low engine rpm and/or zero pressure in the implement circuit, or

- Key off, frequently inferred from the fact that the machine is not transmitting data and/or has sensors that show it to be powered down, not moving, and with zero pressure in any implement circuit.

What defines a machine's operational status?

Specialists in operations analysis and productivity improvement have studied the performance of construction equipment since Day 1. They have developed their techniques and their language and have a long history of success in helping companies improve the quality, productivity, and safety of their operations. It is a skilled combination of art and science based on observation, experience, analysis, and judgment. Can the work be done better, can delays and disruptions be minimized, and can resources be used to the best of their ability?

This is not the place to go into detail on those techniques. Suffice to say that specialists in the area frequently define the high-level operational status of a machine as either:

- Working: The machine is on site, able to work, and is being used to complete tasks associated with required work. There are, of course, varying degrees of efficiency or productivity within working time and this is, in and of itself, a specialized subject.

- Stand-by: The machine is on site, able to work, but is not being used to complete tasks associated with required work for any number of operational reasons. There are, of course, various reasons for stand-by time: Most are associated with the planning, sequence, and flow of the work.

- Down: The machine is on site and required to work but is not able to work because of some mechanical problem that makes it impossible, unwise, or unsafe to operate.

- Undeployed: The machine is not deployed to an active work site and is not expected to work.

The question now arises: What is the relationship between sensor status and operational status?

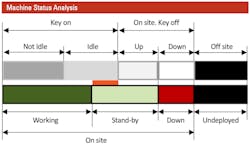

The diagram above shows sensor status on the top line and operational status on the bottom line and makes it possible to draw the following general conclusions.

“Working” time is likely to be greater than “Not Idle” time, as not all required work demands that the machine is at high rpm, moving, or has high implement-system pressures.

“Stand-by” time can be greater than “Idle” time as machines in “Stand-by” status are likely to be either powered down or in “Key off” sensor status and therefore not producing sensor data.

“Key on” time can be used as a reasonable proxy for “Working” time if time spent in “Idle” status while on “Stand-by” (the orange overlap) is small, negligible, or closely managed.

Four ways sensors could define operational status

Four additional factors need to be considered.

- First, there are no generally accepted sensor outputs or algorithms available at this time that can be used to measure downtime and to determine whether the machine is either “Up” (able to work) or “Down” (not able to work) when in “Key off” status.

- Second, time spent in “Idle” status while on “Stand-by” (the orange overlap) is truly a waste from a fuel consumption, component life, and machine life point of view. Time spent in the orange overlap must be managed. Machines that are on “Stand-by” should be powered down.

- Third, engine idling time is not and should not be seen to be a proxy for “Stand-by” time. Many well-planned working cycles include periods when a machine’s engine is at idle. It is simply not correct to assume that a machine is not engaged in required work simply because it is not in gear, not moving, or the engine is not at high rpm.

- Fourth, most sensor systems include GPS position data and geofencing algorithms that make it possible to measure the time a machine spends deployed to an active working site. This makes the calculation of deployment a simple and straightforward task.

The vision of a self-reporting machine that records and wirelessly transmits its operating status is a worthwhile goal that is still to be realized. The principal reason for this lies in the differences between the various proprietary and, more often than not, closely held algorithms used to draw inference from sensor data. These vary tremendously across the industry, and there is too much at risk in the costing and estimating process to allow equipment costs and productions to be made vulnerable to unknowns and variations in both sensor data and proprietary third-party algorithms.

Every car’s speedometer uses a sensor on the driveshaft and a simple well understood algorithm to provide information regarding the speed at which the car is traveling. This is not yet the case with sensor-based systems and the associated algorithms used for construction equipment.

About the Author

Mike Vorster

Mike Vorster is the David H. Burrows Professor Emeritus of Construction Engineering at Virginia Tech and is the author of “Construction Equipment Economics,” a handbook on the management of construction equipment fleets. Mike serves as a consultant in the area of fleet management and organizational development, and his column has been recognized for editorial excellence by the American Society of Business Publication Editors.

Read Mike’s asset management articles.