Ensure Data Integrity in Fleet Management

Equipment management requires various equipment-specific software systems and technologies to effectively manage fuel consumption, inventory, operational costs, utilization, risk, productivity, and other essential areas. Sound equipment management decisions rest on the foundation of high-quality detailed data, and its accuracy is of the utmost importance.

Evolving technology provides managers access to specialized industry-specific computer systems and applications. These highly advanced systems import and calculate specific data from a myriad of sources. They analyze an almost infinite number of data sets in their effort to calculate and predict future events with increased speed and accuracy. As managers understand the advantages to such systems, deployment is swiftly increasing in fleets.

Visit Equipment Executive Institute for more asset management.

As reliance upon these predictive systems steadily increases, maintaining accuracy, integrity, and consistency of the base data becomes increasingly important, requiring focus, consistency, and management. Data within these systems must be reliable, accurate, and consistent over the equipment’s lifecycle. It must be free of errors, and all required data fields must be identified accurately. Any compromise decreases the data reliability, subsequently reducing its effectiveness and accuracy.

Managers must consistently emphasize and ensure the integrity of the base data input, housed, and shared within these individual systems.

Define the date entry process

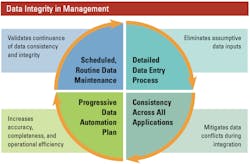

Detailed policies defining the data-entry processes eliminate assumptions made by various data-entry personnel across the various computer system applications deployed by the organization. Data policies and procedures should define the processes for raw data entry and application integration in order to increase consistency and mitigate or eliminate data conflicts across the specific applications deployed throughout the organization. Without strict adherence to specific data policies and processes, the possibility of erroneous, inconsistent, or missing data significantly increases, creating an inaccurate set of cumulative values that potentially lead to mis-informed management decisions.

The process should include a well-defined, regularly scheduled review mechanism to ensure data integrity and mitigate or eliminate data errors. The policy should include a training component for all positions having data entry or application integration duties throughout the organization.

Align data fields for consistency

Consistently reliable data is critical for equipment managers to be successful in their decision making. Inaccurate or incomplete data fields in equipment records account for the vast majority of data inconsistencies. These errors can potentially creep into the various systems through a multitude of sources creating inconsistent equipment data reporting. Left unchecked, such data inconsistency can and will eventually lead to misinformed decisions, potentially jeopardizing the organization’s competitiveness. Two areas of focus are the CMMS data-entry process and associated systems integration processes.

Accurate CMMS data entry input is crucial for long-term data integrity. Such data is relied upon by equipment managers throughout the machine’s lifecycle to make the necessary assignment and repair/replace decisions. Typically, equipment-specific data is input manually, usually by individuals assigned to various business centers and functions within the organization, each concentrating on their specific area of expertise. Most data conflicts will enter the systems at this point in the process. Unintentional spelling and numerical errors, as well as blank data fields, are common data input miscues.

All data fields in the equipment record should be completely and consistently filled. Acronyms should not be utilized as they do not hold consistency across the various disciplines of the organization. For example, the equipment manufacturer field should be identified by the manufacturer’s full name, not its trademark acronym or other designation. A review process is critical to reduce and eliminate these common initial data-entry errors.

Successful equipment decisions depend on data consistency across secondary or associated systems and therefore require immense focus. Real-time integrations normally are fully automated where any potential conflicts have been previously identified and corrected. Periodic or flat file integrations generally are not fully automated, requiring a subsequent review of the data before importing to eliminate any erroneous data import. Equipment data should be input into each specific application following the same rules as the CMMS data-entry process to mitigate or eliminate system conflict. Doing so significantly increases the likelihood that data housed in the various systems will remain consistent throughout its integration with the CMMS.

Automate relevant, repetitive tasks

Automating repetitive data entry and collection saves time and eliminates many of the minor errors previously discussed that compromise accuracy and consistency. Data entry and integration become a much smoother, efficient process ensuring a high level of accuracy and consistency within the various system data sets. Automation benefits new-employee onboarding development as well as increasing staff efficiency. Technicians and data-entry staff do not have to meticulously enter detailed information manually because software imports the key information relative to the specific data field. Consistency across multiple facilities is greatly increased, and efficiency increases allow staff to concentrate on more advanced assignments. A progressive automation and advancement plan for all computerized systems should be integrated within the organization’s business plan, and its funding an organizational priority.

Maintain data integrity

Strategic and timely data cleansing (or scrubbing) is the final step, necessary to maintain consistency across the multiple system applications over time. It validates that the data remains accurate and complete within a system or across the various applications. Data cleansing involves both computer programing and staff review to validate data integrity using rules, processes, and procedures designated by the organization. Exception reports can be established and run automatically to validate equipment records for integrity and consistency in all system applications. Typographical errors and incomplete data fields are identified and either corrected or deleted, as necessary. This process must occur simultaneously for all systems integrated to ensure data consistency across the organization. The value of such data cleansing increases significantly when an organization operates over a wide geographical area or has multiple facilities as data inputs from all facilities must maintain similar accuracy and consistency. Without this data-cleansing process completed regularly, mistakes and errors escalate, leading to less efficient work and increased complications.

Whether relying on basic computing systems, on the cutting edge of computing technology, or somewhere in between, every equipment-management decision and action rely on accurate and consistent data. Any compromise made in terms of data consistency or integrity will eventually surface within a critical, time-sensitive decision with no time to correct.

Ultimately, it takes increased effort and focus initially to develop sophisticated data-management processes to run a first-class equipment management organization. The results of such effort will enhance the accuracy of the decision-making process and long-term efficiency and effectiveness of the organization.

About the Author

Mike Brennan, CEM

Michael Brennan is a 40-plus-year industry veteran and consultant in vehicle and equipment maintenance management. A three-time recipient of the AEMP Fleet Masters Award, he focuses upon process improvement, facilities management, succession planning, technology, and lifecycle analytics as the cornerstone of success in the equipment management industry.

Read Mike's asset management articles.