Maximizing the productivity and cost effectiveness of construction equipment is the foremost objective of maintenance managers. To reduce unscheduled downtime and cost, they use a sophisticated preventive maintenance program tailored to maximize the efficiency of each type and class of equipment deployed within the fleet. Such programs include detailed inspections and fluid analysis/exchange at specific usage intervals, as well as predictive component rebuild/replacement based upon OEM or historical data.

All these planned maintenance functions are the responsibility of and performed by the maintenance department.

See the Institute for more asset management.

Yet maintenance technicians are in high demand, and they cannot cost effectively visit every machine every day to ensure complete readiness for the shift’s productive work schedule. A sound operator-care program becomes a critical component in reducing downtime and cost.

Operations and maintenance managers have a shared incentive to reduce downtime and cost. Maintenance managers must relay to operations managers the value of enlisting equipment operators to perform basic maintenance or “operator care” functions in order to maintain equipment productive potential and cost effectiveness. Without it, operations are likely to suffer loss of production or incur increased cost. Most unscheduled downtime is the result of a small, minor defect that increasingly worsens to the point of failure over an extended period of time. Typically, it could have been corrected prior to failure had it been detected in its early stages. The operator, who spends the most time with the machine and has knowledge of its operating characteristics, becomes the first line of defense against unscheduled failures, increased downtime, and cost.

Operator care requires full support from the executive branch of the organization and commitment from operations to allocate the time to perform the necessary tasks as scheduled. In turn, the maintenance department must develop the operator-care task list and schedule, and keep the functions at a basic-maintenance level requiring few tools to complete. Maintenance should train the operator concerning the importance of proper and timely inspection, how to perform the inspections, a review of all lubrication points, and how to make minor field adjustments. The appropriate tools and equipment required must then be allocated to operators.

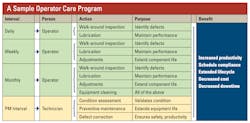

An operator care checklist, lubrication chart, and schedule should be developed specific to the machine type and class (see above). Most equipment manufacturers provide a recommended daily/weekly/monthly service and inspection schedule and periodically required field adjustments. This information combined with historical failure analysis allows for the creation of a comprehensive walk-around operator inspection and checklist ensuring all lubrication and critical failure points are regularly lubricated and inspected. For example, lack of timely lubrication or an improperly adjusted undercarriage can reduce the operational life of the undercarriage components by 10 to 15 percent, causing increased unscheduled downtime and increased undercarriage cost.

Such inspections and operator-care functions should become a standardized operator routine, completed at the beginning of the shift, between shifts, or during fueling in order to identify any potential defects, fluid leaks, blocked lubrication points, or any irregularities that worsen, potentially compromising the operation of the equipment. Any defects or irregularities discovered during inspection or normal operations of the equipment should be noted on the checklist and reported to the maintenance department on a regular basis—immediately, if a safety defect or imminent failure of a critical operational component or system is identified.

Most unscheduled downtime is the result of a minor defect that worsens to the point of failure over an extended period of time.

Periodic machine cleaning should be incorporated into the operator care program. Removing excessive dirt and debris buildup enables early detection of loose fasteners, fluid leaks, developing cracks, or excessive wear. Additionally, a clean machine indicates routine care is being performed, reassuring management of the operators’ respect for the machine and its productive capability.

Completed operator care inspection checklists and deficiency reports should be regularly reviewed by maintenance personnel and added to the asset record. Safety-related defects require immediate corrective action, while other defects possibly can be deferred and scheduled for repair at the next PM milestone. Operator care checklists can also be electronically developed, accessed by operators and technicians through their phones or tablets, and transmitted directly to the CMMS asset record and equipment department, significantly increasing the timeliness and scheduling of repair.

A plan to address the proper care and lubrication requirements for each type of equipment is critical and should be examined carefully.

Primary/critical equipment generally will have a dedicated operator and follow standard operator care guidelines as described within the plan.

Secondary/associated equipment may not require a full-time operator or have multiple operators, in which case a dedicated operations team member or maintenance technician is required to perform the required operator care. Fuelers routinely are tasked and trained to perform the required inspections and lubrication on this type of equipment while fueling, given time is available within the fueling schedule.

Administrative/support vehicles and equipment are inspected by the operator at the time of fueling. Such inspections include a simple walk-around inspection and fluid check noting any discrepancies on a defect report turned in to the maintenance department. Exceptions are vehicles that fall under the on-road commercial vehicle compliance regulations and require a documented specifically detailed daily operator pre- and post-trip walk around inspection. All assets within this equipment type are typically mobile and driven to the maintenance facility for defect correction by shop personnel or deferred until the next regularly scheduled PM service.

Consistency is key, and like other programs or processes, an effective operator-care program must be managed. Some sort of measurement component will ensure compliance and continuous improvements. In managing the program, operator care checklists should be reviewed for completeness and deferred defect repairs addressed at regularly scheduled PM intervals. The assigned maintenance technician should confirm proper and timely lubrication is being performed, noting such on the PM checklist. Compliance in performing such operator care and the timely submittal of the checklists should be a key component of the operator evaluation process.

The effectiveness of an operator-care program can be measured by analyzing mean time between failure. Theoretically, an increase in the lubrication and primary care of specific components should extend the mean-time-between-failure rate of such components. Conversely, inconsistent or lack of proper care will decrease the failure-rate interval, identifying the need for additional training or adding additional checks or lubrication points to the checklists.

Unscheduled failures can’t be totally avoided, but they can be significantly reduced by an effectively managed and properly performed operator-care program. Such a program increases productivity and reduces downtime and cost by identifying potential failures in their infancy, allowing for timely and scheduled adjustments/repairs. The machine or a specific component’s lifecycle is also extended through the proper care, cleaning, lubrication, and the periodic adjustments performed by the operator. Compliance and consistency are the key.

About the Author

Mike Brennan, CEM

Michael Brennan is a 40-plus-year industry veteran and consultant in vehicle and equipment maintenance management. A three-time recipient of the AEMP Fleet Masters Award, he focuses upon process improvement, facilities management, succession planning, technology, and lifecycle analytics as the cornerstone of success in the equipment management industry.

Read Mike's asset management articles.