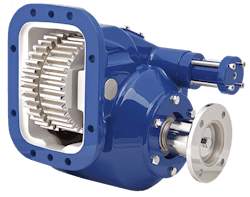

The power take-off (PTO) on a work truck, utility vehicle, or tractor can be a critical part of the hydraulic system, transferring vehicle engine power to auxiliary components for any number of applications on a job site.

Since it’s mounted to the transmission, PTO failure can cause expensive downtime.

Charles Cole, product application specialist for Muncie Power Products, says PTO maintenance is often neglected. He told his company’s latest Muncie Power Quarterly publication that part of the challenge of PTO maintenance is the lack of guidelines for creating a maintenance schedule—as there’s no set standard due to varying factors that impact the PTO, including load and application type.

That means a manager would have to determine a maintenance schedule on a case-by-case basis. “It becomes tribal knowledge,” Cole says. “The life of a PTO can vary greatly based on the amount of horsepower required by the application.”

According to Cole, some PTOs may only log 10 to 15 minutes per week, while others could see action 10 to 12 hours a day. Whatever the use level, all PTOs should be checked within a week or two of installation to make sure the mounting bolts have been torqued properly.

“A visual inspection of the PTO needs to be done weekly,” Cole says.

The inspection should look for leaks, signs of wear, and that the hose and wires are secured to the PTO and not rubbing against the transmission/other components. That kind of friction can lead to fraying and leaks. Cole also advises users to listen for any changes in normal sounds during operation.

“A good practice to follow is to perform the PTO maintenance along with regularly scheduled oil changes and checks because the PTO and the transmission use the same oil for lubrication and operation,” Cole says.

If there are no red flags during a visual—or aural—inspection, Cole recommends performing the first physical inspection for severe-duty applications after 100 hours. And if you see extensive wear then, schedule physical maintenance more frequently.

Some PTOs may be inspected by removing an inspection cover; others require the removal of the PTO from the transmission. If you remove the PTO, the company says you should check the gears for unusual wear patterns and the bearings for smoothness or pitting.

If a look at the gears and bearings reveals no issues, replace the gaskets and the shaft seal. If the pump is remote mounted, check the drive shaft. Otherwise, with a direct-mount pump, periodically clean and grease the pump splines where it connects to the PTO.

You can see more issues of the publication here. Muncie’s general website also lets you configure a PTO design online.