In the early 1900s, large-volume mass excavation projects posed a challenge, given the limitations of available technology. As a result, some quite unusual machine designs grew out of the need to move large amounts of earth as quickly and economically as possible. One such was the Templet Excavator, built in the 1890s by the F. C. Austin Drainage Excavator Co.

With its variant spelling of “template,” this ungainly machine traveled on rails or crawlers and straddled the excavation. The rail-mounted version rode on temporary track that was removed from behind the excavator and placed in front of it as it moved forward.

A digging frame, shaped to the cross section of the ditch to be excavated, was lowered to contact the ground. A single bucket shuttled back and forth along the frame, digging from the ditch slope and invert and dumping clear of the ditch by means of a trip mechanism. The digging frame was lowered with each pass, and when its base reached final grade, it was raised clear, and the machine advanced three feet and repeated the process.

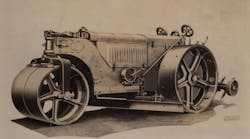

The Templet Levee Builder, shown in this image, was a variant of the Templet Excavator. On this version, the frame extended from both sides of the machine. One end was shaped to the excavation and the other was suspended over the centerline of the levee to be built with the spoil. The bucket, with a capacity of 1-1/3 to 2 cubic yards, was drawn through the cut, across the machine, and up to the opposite end of the frame, where it was dumped and then drawn back for another pass.

The house containing the machinery and the operator’s station was 22 feet long by 20 feet wide, and the machine traveled on flanged wheels atop 200 feet of 12x12 timbers. It required an operator, fireman, two men to move the track sections, a team of horses to move the timbers the track rested on, and another man and team to haul fuel and supplies. It could excavate 100 cubic yards an hour in favorable conditions.

Nothing else is known to this author about these machines, but they apparently were not in production for long; the advent in the 1910s of draglines and scrapers (which provided a practical means for large-scale ditch and canal excavation, as well as levee construction) likely was responsible for their demise.

The Historical Construction Equipment Association (HCEA) is a 501(c )3 non-profit organization dedicated to preserving the history of the construction, dredging and surface mining equipment industries. With over 4,000 members in twenty-five countries, our activities include operation of National Construction Equipment Museum and archives in Bowling Green, Ohio; publication of a quarterly magazine, Equipment Echoes, from which this text is adapted, and hosting an annual working exhibition of restored construction equipment. Our 2016 show is September 16-18 at our Museum. Individual memberships are $35.00 within the USA and Canada, and $45.00 US elsewhere. We seek to develop relationships in the equipment manufacturing industry, and we offer a college scholarship for engineering students. Information is available at www.hcea.net, or by calling 419.352.5616 or e-mailing [email protected].