Managers of mixed fleets continue to wrestle with aggregating deep machine data flowing from several manufacturers. The ISO (AEM/AEMP) telematics standard provides only limited data points, and most fleet managers do not have the data analytics expertise to built their own system.

Clue Insights, with majority backing from Doosan Infracore, has developed a proprietary machine data platform that aggregates information from multiple equipment manufacturers as well as from third-party telematics firms. The customizable platform integrates and normalizes machine data through the various APIs and provides a single “pane” of information to the fleet asset manager.

“We integrate any ECM and sensors data provided by OEM [telematics systems], including engine hours, odometer, fuel and DEF consumption, fault codes, engine idling, and other data that is specific to each asset type, such as load counts, implement status, and more,” says cofounder Oded Ran. “We then augment this data with additional GPS and ECM data obtained via third-party trackers....Running our proprietary artificial intelligence engine allows us to generate high frequency, minute-by-minute insights from all these data points.”

Palmetto Corp., a site development contractor in South Carolina, uses the Clue platform in managing its mixed fleet of more than 900 mobile assets. Darrin Sheriff, director of equipment and purchasing, said Clue built a platform for all the data Palmetto wants to track.

“Clue reports our key metrics on a daily and weekly basis,” Sheriff says. “Using the system, our idle rate dropped from 60 percent to 20 percent, on average, since [we started using Clue in] October.

“We’ve probably saved a couple hundred thousand [dollars] since December,” he says, citing one example of a leak on a backhoe loader that was identified and repaired, saving $17,000 in costs.

The data is available in real time, which means Sheriff can place “eyes” on any machine in the fleet while staying close to home.

“I used to drive 50 to 60,000 miles a year,” he says. “Since the end of January, it’s been 6,000 miles because I don’t have to be there to see what’s going on. That creates a huge amount of efficiency. When I can see what’s going on 4.5 hours away in real time, that’s priceless.”

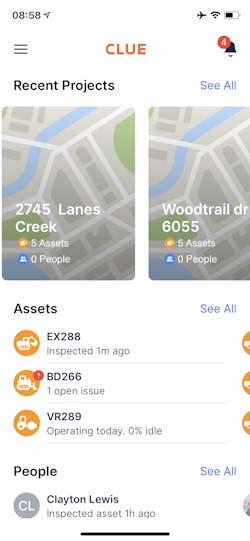

The platform includes a smartphone app that allows everyone in the company to check machine status. The app includes machine inspection forms, which has improved accuracy and timeliness. In addition, Clue has integrated a “create work order” function and PM interval inspections into the system.

“You’re on a job, starting the day on a dozer,” Sheriff says. “You open up the app, click on your asset, press the tab to do the equipment inspection. Click ‘report a fault,’ add a comment such as 'boom cylinder is leaking,’ and add a photo. If the asset doesn’t have engine telematics, then you can input manually. Once you report it, submit it and confirm. Within a second, a push notification goes to the shop foreman. He taps on it, reads it, and can create a work order. He can assign it to a mechanic.”

The platform tracks the work order, so anyone connected to that machine knows its status, from the operator to the technician to the job superintendent to upper management. Sheriff says the transparency of the platform has reduced the time shop management spends answering requests for machine status.

Palmetto now has 170 employees using the platform daily, including field crews, mechanics, and senior management.