“More Power!”—it was a catchphrase in the “Home Improvement” comedy series, but it’s also a demand many contractors make of their construction and mining equipment, pressing manufacturers for machines that can do more in less time. The ways of developing and applying “more power” are extremely varied, however, and the term doesn’t just involve applying more horsepower to a given task.

In 1960, Guy F. Atkinson Co. was awarded the prime contract for Briones Dam, a water-supply project in the hills near Oakland, Calif. The approximately 10 million cubic yards of embankment material involved in the project could be handled by scrapers (a fleet of a dozen 40-cubic-yard Euclid SS-40 models, assisted by eight Cat DW21 scrapers, which were later replaced by 10 more SS-40s). Compacting this material, however, was another matter.

The Historical Construction Equipment Association is a 501(c)3 non-profit organization dedicated to preserving the history of the construction, dredging, and surface-mining equipment industries. Individual memberships within the USA and Canada are $35 for one year, $66.95 for two years, $99.95 for three years, and $45 US elsewhere. Information available at www.hcea.net, or call 419.352.5616, or e-mail [email protected].

Initially, compaction was done with sheep-foot rollers, a pair of 50-ton pneumatic proof rollers, and a Hyster C410A pad-foot compactor. Cat D-8 crawlers pulled the sheep-foot drums, and DW-21 prime movers drew the Hyster and the proof rollers. But the material contained a significant amount of rock, and the composition of the material defied efforts to compact it to specification.

Buster Peterson, employed by the regional Cat dealer, Peterson Tractor Co., had established a reputation for creating innovative machine designs and making machine modifications in order to resolve difficult problems—and Buster tackled the compaction situation. His solution was the Dual 631 compactor, nicknamed Stomper. The machine consisted of two 631A prime movers and had pad-foot wheels in place of tires. The prime movers were yoked together end to end, with an operator’s station in front and the engines trailing. Its speed and considerable weight were more than enough to deal with compacting the obstinate material on the Atkinson job, and the dam was finished in 1963.

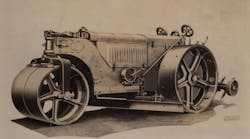

A second such machine was assembled at some point, and in 1963, Atkinson put two machines it termed “631A crusher/compactors” up for sale. Then, from 1963 through 1965, Atkinson used a rubber-tired, tandem 631A push-loader (shown) on the section of California’s San Luis Canal that it built; this machine was listed for sale afterwards.

Peterson went on to build another compactor, the 70-ton Twin 631B Tamper, with both tractors running forward, joined by an entirely redesigned yoke, and rolling on Hyster C400B wheels.

Peterson Tractor’s history book mentions only two Dual 631s, the Briones 631A and the 631B. The origin of the second tandem 631A is a mystery; Peterson surely had a role in it, and the only logical conclusion is that it was omitted from the history and/or assembled by Atkinson using components from Peterson. It’s also logical to conclude that one of the “stompers” was converted to the push loader. Final dispositions of these remarkable machines are unknown.