The Ruth Dredger was a unique trench-digging machine that served a niche market for many decades. It was invented in 1906 by Charles H. Ruth, a blacksmith in the Imperial Valley of California. At that time, huge amounts of silt brought down by the Colorado River were being deposited in the Valley and repeatedly clogging the many irrigation ditches fed by the river. After experimenting with several types of primitive machines, irrigation companies declared the Ruth Dredger the most economic of all because of its continuous action and high-volume capability. Following its success in California, the Ruth Dredger Manufacturing Corp. was established in Los Angeles, and it wasn't long before Ruth Dredgers were at work in many states constructing and cleaning irrigation ditches, cleaning canal banks, and building berms and levees to control flooding.

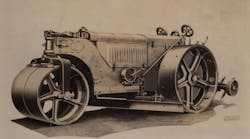

The extraordinary flexibility of the Ruth ditching machine was due to its swinging boom that carried the digging buckets. The boom could swing 90 degrees, left or right, positioning the buckets to trim ditches or canal banks on either side of the machine as it moved ahead. The upper picture shows the machine in travel position with buckets raised above ground and pointing to the rear. The main machine was supported on a single crawler track while a second stabilizing track, not visible in the picture, could be positioned at the far side of the ditch. This remote stabilizing crawler was connected to the main machine by a telescoping frame, adjustable to 25 feet in length, and powered through a telescoping drive shaft connected to the main machinery. This enabled a ditch to be cleaned as the machine straddled it with the buckets positioned between the two tracks.

The lower picture shows the outer end of the telescoping frame in the retracted position and an operator adjusting the steering angle of the crawler assembly with a hand crank arrangement operated through a worm drive.

The early Ruth Dredgers were mounted on three wheels, two under the main machine while the third supported the remote propelling assembly on the far side of the ditch. In the early 1920s, the wheels were changed to a crawler track under the main machine but a wheel was still utilized for the remote position. A few years later, the wheel was abandoned altogether and a two-track configuration was adopted.

In 1939, Bucyrus-Erie acquired the rights to its manufacture and commenced building the machines under the Bucyrus-Ruth trade name. Model HU was powered by a 32-flywheel-hp Cat D4400. Variable digging speeds were available from about 3 to 80 fpm, and the entire machine tipped the scales at 18 tons. Very few of the Bucyrus-Ruth machines were sold so, with the onset of World War II, the company officially discontinued the product at the end of 1942.

You can read more about the evolution of construction equipment in Keith Haddock's book "Giant Earthmovers an Illustrated History" available in most bookstores. Also, consider a membership in the Historical Construction Equipment Association, www.hcea.net .