The well-known Gradall excavator, with its rotating and telescoping digging boom, has served a niche market since the early 1940s. Its unique bucket movements and array of attachments enable it to perform far more than your average excavator, with an extra payback on finishing work for which there is no equal. Now owned by the Alamo Group headquartered in Seguin, Texas, the Gradall Co. still builds its excavators in the factory at New Philadelphia, Ohio, where more than 15,000 have been built since 1950.

But in the early years, Gradall didn't have it all its own way. Several other manufacturers tried to take advantage of the Gradall principle and brought out similar versions of a telescoping excavator. In America, Link-Belt's Rotascope, Warner & Swasey's Hopto Hydro-Scopic, and Quick Way's Grademaster experienced varying degrees of success.

The Grademaster, designed and built by Quick-Way Truck Shovel Co. of Denver, Colo., was initially developed from an earlier attachment to the company's regular truck cranes. Founded by Luke E. Smith, the Quick-Way company had achieved significant success with its truck cranes and claims to have built America's first truck-mounted shovel in 1929.

The crane attachment, originally known as the "Chore-Master," was announced in 1957 as "the first interchangeable hydraulic grading-digging attachment that makes dozens of jobs possible with one machine." Its part-cable, part-hydraulic design incorporated a telescoping boom with a rotating bucket at its end. The boom itself did not rotate. Two large hydraulic cylinders and one hydraulic motor operated the bucket rotation, bucket tilt and telescoping boom, but hoisting the boom was by cable from the crane's standard winding drums. The Chore-Master could be interchanged for a regular crane boom to work as a crane, dragline, clamshell or pile driver.

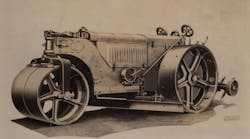

The cumbersome cable/hydraulic hybrid design was replaced in 1960 by a new single-purpose fully hydraulic machine known as the Grademaster. It was equipped with a fully rotating boom that could telescope 14 feet to achieve a working radius of 31 feet 8 inches. Power came from a 99-hp gasoline engine and the hydraulic system operated at a maximum pressure of 1,600 psi. When mounted on a 6×4 carrier with a 182-hp International Harvester gasoline engine, the Grademaster could dig down 18 feet with a ¾-yard bucket, and the entire outfit weighed 44,500 pounds.

Marion Power Shovel Co. of Marion, Ohio, looking to expand its small machine line, was attracted to Quick-Way products and acquired the company in 1961. It continued as the Quick-Way Crane-Shovel Co. and operated as a division of Universal Marion Corp. A short time later, Marion changed its focus to larger machines serving the surface mining industry, and the Quick-Way products were discontinued.

You can read more about the evolution of construction equipment in Keith Haddock's book "Giant Earthmovers an Illustrated History" available in most bookstores. Also, consider a membership in the Historical Construction Equipment Association, www.hcea.net.