George Haiss soon began thinking of ways to make the business more efficient. Loading coal into trucks by hand was slow and tedious, so he invented labor-saving devices such as clam buckets and conveyors that could be raised to hoist the coal into trucks. His devices attracted the attention of others keen to purchase them for their own use, and eventually the Haiss company became solely involved in manufacturing, changing its name to the George Haiss Manufacturing Co. of New York.

In 1913, Haiss began making elevator loaders powered by gasoline engines. These machines could load sand or gravel direct from the bank, and crushed stone or other materials from stockpiles. In 1918, the company originated power crowding (wheel drive) so that the loader could propel itself slowly into the bank. At the same time, Haiss patented a force-feeding device (spiral propellers) that fitted in front of the machine. This enabled material to be collected from a wide path, reaching outside the machine width, and maximizing the load in each elevator bucket.

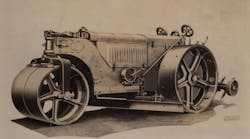

The company produced a variety of wheeled and crawler-mounted models and, by 1934, machines capable of loading up to 8 cubic yards a minute were being offered. The crawler-mounted "Path-Digging" Loader, originating in the 1920s, was a powerful digging machine built to heavier proportions so it could be used in road construction and excavation of consolidated material with the exception of rock.

Propelling speed was up to 100 feet per minute when relocating and 2 feet per minute when digging. Simple differential steering was actuated by applying a brake on a drum adjacent to the final drive sprocket on either side of the crawler frame. Stated output was 2 cubic yards per minute and each bucket held about 0.5 cubic foot. Power was supplied by a 37-hp Waukesha gas engine, and the machine tipped the scales at 7.5 tons.

In the mid-1940s, while still run by several members of the Haiss family, the George Haiss Manufacturing Co. became a division of Pettibone Milliken Corp. The new owners continued to offer Haiss bucket elevating loaders until the machines were superseded by more efficient wheel loaders in the early 1960s.

You can read more about the evolution of construction equipment in Keith Haddock's illustrated book "The Earthmover Encyclopedia" available in most bookstores. You may also consider a membership in the Historical Construction Equipment Association, www.hcea.net.