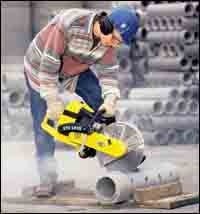

For cutting through thicker walls to make square openings, the concrete chain saw is a wise choice. The chain saw can cut square corners without overcutting.

| In this story: |

|---|

Many variables come into play when looking for a concrete saw for rent. But it all comes down to finding the right saw and blade for the work at hand. First, consider the various types of ways to power the saw.

Gasoline concrete saws

Gasoline-powered saws offer true portability because they don't require a separate power source. But gasoline-powered saws also involve the complexity of the internal combustion engine. Concrete saws typically use two-stroke engines, the kinds where oil and gasoline are combined. Make sure that whoever is using the saw realizes that the gasoline requires the proper oil mixture. Two-stroke engines are less complex than four-stroke engines.

Contaminants are the enemies of concrete saws. Dust, grit and moisture can lead to engine problems, although many saw manufacturers have developed filtration systems that help eliminate many of the problems associated with infiltration. For instance, concrete-saw manufacturer Partner developed a three-step filtration system that filters out virtually all contaminants. Vacuum systems and water application also help control dust, both to the saw and the environment.

Gasoline-powered saws also cannot be used in enclosed areas because of the fumes they create. This is one of the reasons why the saw renter may want to consider other power sources, if available. Hydraulic saws operate from a remote power source, are lightweight, and easy to handle. Since the power source is away from the job, it can be protected from any dust created by the job. Moving parts typically are sealed, reducing maintenance. Some hydraulic saws can even be operated underwater. Because they produce no fumes, hydraulic saws are ideal for indoor use. If the renter already has a hydraulic power pack that matches to the saw, only the cost of the saw is involved. If not, one will have to rent the power pack as well. Hydraulic power packs can weigh a couple of hundred pounds and are powered by either gasoline or electricity, which may restrict where they can be used.

Pneumatic Concrete Saws

If one has an air compressor, consider renting a pneumatic saw. As with hydraulic saws, pneumatic saws are lightweight and have few moving parts. Both pneumatic and hydraulic saws start on demand and require little maintenance or ongoing service.

Electric saws, like gasoline saws, have a built-in power source. They're quiet and release no fumes. If electric power is available, you're in business. But if you're working in a remote area, you'll need a generator. However, as with air compressors, most contractors have generators. Another power possibility is propane. Here, a propane tank is required.

Types of concrete saws

Three types are available when looking for a concrete saw to rent: hand-held, walk-behind and table-mounted. The table-mounted saw typically is used to cut masonry and brick. Hand-held saws, called cut-off saws because they often can cut materials other than concrete, come in many sizes and types and can be used to cut both vertical and horizontal surfaces. In addition to saws with circular blades, chain versions also are available. Two advantages of chain saws are that they can cut thicker surfaces and, when used to cut openings, can cut complete square corners without overcutting. Today's hand-held concrete saws for rent are lighter weight than their predecessors and are highly mobile.

For cutting into concrete or asphalt horizontal surfaces, there are the walk-behind saws. These heavy-duty tools are designed for extensive cutting operations and can be quite heavy. Most are gasoline powered. Carts or cradles are available to turn a hand-held saw into a walk-behind one, but are not recommended for concrete sawing. The cart also can pose a safety hazard when it gets old. When renting a walk-behind saw, check the mechanism that raises and lowers the blade to make sure it sets the blade accurately and secures it in place.

Concrete saw blade selection

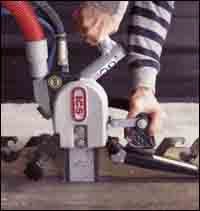

As important as finding a concrete saw to rent for the job, if not more so, is selecting the right kind of blade. Assuming that concrete is the material to be cut, the pros recommend using a diamond blade. But diamond blades come in a variety of types suited to the hardness of the material. To understand how to select a blade, you need to know how diamond blades are constructed. High-quality, synthetic industrial diamonds are imbedded in a matrix of powdered metals. As the saw cuts through the material, the matrix wears away, exposing new diamonds and releasing old ones. The matrix wears away at the same rate as the diamonds for maximum efficiency. When cutting softer material, a blade with a harder matrix is used. Because the diamonds last longer in softer material, they don't have to be sluffed off as quickly. Harder material requires greater replenishment of the imbedded diamonds, thus the matrix wears away more quickly.

Other blade considerations include size. A larger blade may cut deeper, but can make the saw harder to handle due to the gyroscopic effect. Although diamond blades are more expensive to rent than abrasive ones, they are highly recommended for cutting material such as concrete.

The hardness of the material to be cut can range from hard rock such as granite to asphalt. In between, one can find a range from hard brick, different types of concrete and concrete block. The region of the country also influences the type of concrete, since the hardness of the sand or aggregate used to produce the concrete varies. The hardest aggregate is found along the easy coast, in the west and parts of the deep south. The softest material is found in the Midwest and Plaines states. All are factors when selecting the right blade, and then the right saw.