How the Pandemic Affects Equipment Planning

Equipment managers have commenced planning for 2021 as business activity slows and their organizations close out 2020. Most will find that the pandemic upended their organizations to significantly alter, or in some cases completely abandon, their strategic business plans. They developed and deployed assumptive policies and subjective operational protocols and procedures.

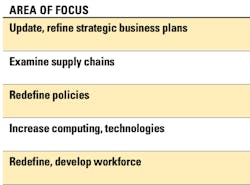

Organizations will struggle with defining an expected “new normal” of business operations as they develop strategic plans and goals for 2021.These five areas must be considered.

Strategic planning

Although most organizations’ mission and core values should not change, their annual and long-term vision or outlook may require refinement. Team-based strength, weakness, opportunity, and threat (SWOT) analysis and strategic planning sessions to analyze and update the organizational structure, equipment requirements, and overall business strategies will identify new strategies to increase efficiency, maintaining consistency, and achieve successful results.

Want more on asset management?

The continuance of profitable workflow will require aggressive marketing and business development. Meeting financial benchmarks and goals such as revenue, profits, margins, and equity will be heavily dependent upon the implementation of updated and innovative processes in cost estimating, project management, and management of the workforce. Developmental plans for each should be clearly identified within the plan along with updated processes, procedures, and specific measurable milestones.

Supply chain evaluation

Supply chains are complicated delivery systems for moving parts, materials, supplies, and construction machinery from the manufacturer to the end user. On-time performance of an organization’s supply chain is imperative for reducing downtime and maintaining project schedules. Increasingly, technologies have advanced supply chain expectations to real time visibility—from order to delivery—allowing organizations to accelerate production to decrease the time required to complete a specific task or project.

Many organizations routinely maintain a narrowly focused or single-stream supply chain utilizing a minimal number of suppliers identified to be low-cost high performers. The pandemic has upended most supply chains, disrupting most organizations’ operations over the year. As supplier shipping and deliveries diminished, warehouses emptied, causing most logistics suppliers to significantly extend or completely eliminate delivery guarantees. Projects, machines, and equipment sat idle due to such widespread disruption within the supply chain.

Organizations with single-stream supply chain logistics should be modified and prioritized through collaborative communication with suppliers, manufacturers, dealers, and distributors. Each specific product line should be examined for flexibility in scheduling and sound contingency capability. Those having little flexibility or minimal contingency capabilities should be replaced, or secondary and sometimes a third layer of suppliers should be sourced as backup to the primary suppliers.

Organizational policy

As we continue the transition to a presumptive “new normal,” it is imperative for organizations to review and ensure policies and procedures are up to date and relevant to meet current activities as well as long-term organizational goals. A two-fold approach should be implemented to identify and categorize mandated and sustainable policy versus reactive or mitigative policy.

Long-term organizational objectives and policies established and adopted by the governing body of the organization should generally remain consistent over time. Reactive or mitigative policy changes implemented for contingency operations address contingency policy change caused by uncontrollable industrial or environmental impacts. Some of these reactive or mitigative policy changes will undoubtedly be deemed economically unsustainable when the situation changes.

Frequent policy change increases the potential for confusion and noncompliance throughout the organization’s ranks. To avoid excessive policy change and compliance issues, leadership must differentiate between mandated or sustainable policy change and those that are not. Mandated or sustainable policy changes should be updated or created. Those that are not should be identified as mitigation strategies and categorized within contingency plans for deployment as required to mitigate similar future events. This policy approach positions the organization to quickly adapt to contingencies while maintaining focus on long-term objectives.

The documented contingency or mitigation policies developed to prepare the organization for rapidly changing scenarios and dramatic operational shifts should be reviewed and distributed to all within the organization. Activation of these contingency plans then simply becomes a directive memo to implementation of the pre-established contingency plan, and the anticipated duration.

Computing system and technology

Organizations should review their overall technological capabilities. Those having basic or intermediate spreadsheet-centric computing system capability or experiencing data disconnect will find it difficult to remain competitive in the new year. Such organizations should make it a priority and take immediate action to identify and implement a strategy to advance computing technology. Automation of labor-intensive tasks and system integrations should be given priority, as many technological system and software suppliers are experiencing significant implementation backlogs compounding technological advancement.

Operations are transitioning to a remote workforce, so mobile connectivity is swiftly increasing in value to maintain continuity of operations. Supporting a larger, more diverse mobile workforce requires increased attention and emphasis on connectivity and security. These workers utilize a variety of devices, some of which are personally owned and may not meet minimum system operational requirements. Personal devices may require upgrades or replacement with a device supplied by the organization. Data system security increases simultaneous-ly as the remote workforce increases. Increasing technology to assist with data security such as VPN remote access, anti-virus systems, and stronger firewalls should be addressed.

The impending sunset of the 3G mobile network will require upgrades or the possible replacement of many devices deployed in telematic systems, mobile diagnostic equipment, grade control systems, and other field type technologies. These systems should be implemented if not currently utilized by the organization or updated with the latest software available increasing field productivity and support.

Workforce development

Positions that may have been eliminated or merged will require review and updating of organizational charts. Flexible schedules, remote capabilities and physical working environments will require increased consideration.

A remote workforce requires attention to promote sustained productivity and retain the organization’s culture. The workforce development program will undoubtedly transcend to a mix of both virtual and physical environment settings to attract, recruit, and retain employees. Leadership at all levels will be required to increase mentorship and development of employees to instill innovation and continuous improvement. Goals with specific action plans and expected outcomes should be clearly identified having specific review milestones.

We are about to experience the dawn of a new era in construction equipment management. Organizations who fail to address these challenges will struggle to remain competitive in 2021 and beyond.

About the Author

Mike Brennan, CEM

Michael Brennan is a 40-plus-year industry veteran and consultant in vehicle and equipment maintenance management. A three-time recipient of the AEMP Fleet Masters Award, he focuses upon process improvement, facilities management, succession planning, technology, and lifecycle analytics as the cornerstone of success in the equipment management industry.

Read Mike's asset management articles.