LSU and Rutgers University researchers are collaborating to develop an integrated, multidisciplinary approach to bring emerging robotic technologies, such as a wearable exoskeleton, to the construction industry that will save lives and time.

According to an article in Plant Engineering, researchers received a $150,000 planning grant from the National Science Foundation as part of NSF’s program to develop an exoskeleton. The award gives LSU and Rutgers one year to create a team of researchers to compete for a $3 million research grant in March.

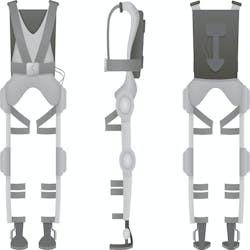

The project has three goals: to develop lightweight, flexible, personalized wearable exoskeletons for construction workers; develop machine learning-based human skill modeling and training in construction; and initiate new cross-disciplinary collaboration with industry partners.

Chao Wang, an assistant professor at LSU, says there are few exoskeleton products currently available on the market, but they mainly target the industrial/manufacturing setting. It is still a new concept in construction because the site is more dynamic and complicated.

“That makes it difficult to design an exoskeleton because you need something that can help with all of these tasks. We are investigating how to make the exoskeleton smart enough to recognize what task the construction worker is doing and adjust its power level and control strategy to more effectively assist with the work,” he says.

The researchers will study what tasks each construction crew member performs in order to develop and train an exoskeleton that fits different construction tasks. They will consider if the robotic exoskeleton should support the upper or lower body and how much power should be given.

The team says its motivation for this project comes from the workforce shortage in the United States. There are plenty of construction jobs but not enough workers. Wang said what caused the workforce shortage is construction workers aging or retiring due to an injury and a decrease in young people doing construction work.