Fleet-management technology has jumped in its sophistication over the past few years, but the most recent leap has ushered in a new era of telematics: Managers can now be connected to every aspect of their fleet at all times of the day. Smartphones enable telematics to alert managers in real time about engine issues, and also tell them the general status of almost any onboard system. With the touch of a screen, managers can check the status of any filter or fluid on any vehicle. They can see if it is time for a service interval, or if that interval can be extended to enable more production before performing routine maintenance.

When it comes to system-monitoring technology, there has never been a better time to be a fleet manager. Yet modern-day telematics are so good at pumping out data every minute of every day, it is easy to become overwhelmed. How do we know what is important?

Zambon is director of Filter Minder for Donaldson.

If a manager doesn’t have the bandwidth to analyze all the data, how do they take action on it? Can we automate it so that the truly important data consistently rises to the top, and if so, can we automate the process of taking action?

Which leads to what Donaldson sees as the next major step in telematics evolution: Data analysis.

Systems such as Donaldson’s Filter Minder Connect provide that analysis. While the manager is provided the data in real time, the system also monitors the sensors, translates that data, and provides useful and actionable information. It works both ways: The fleet manager has everything they need to keep running, and we can better understand their equipment usage to provide more pinpoint service. That relationship will only become more cohesive with time.

At Donaldson, we see fleet data management becoming a partnership with those suppliers of adjacent areas, such as the engine and tires, to integrate information into whatever platform the fleet is using. Instead of having the various information streams separate from the system being used to monitor the fleet, all information from each aspect of the vehicle is available to help the fleet manager make a holistic maintenance decision.

Closer data partnerships lead to better fleet understanding

In many ways, the next evolution in telematics isn’t tech-based: It is collaboration-based. Suppliers can use these advancements in technology to become better partners with each other.

Sharing data between platforms to better serve customers will become easier and easier. With that ease of data sharing, the data will hit more parties organically. For instance, an OEM might be more likely to share data with a filtration expert if the process is automated and seamless, in an effort to provide better support for an end-user.

If every necessary party can access the same data, we will soon be at a place where, when a truck shows an alert, we will be able to diagnose the problem without sidelining the vehicle. And if the truck does need service, the driver could be directed to the nearest authorized service shop. But it does not have to end there. If more parts of the chain are connected, the system could theoretically see if the right parts are in stock or if a technician is available to do the work. If something was amiss, the driver could be redirected. All without ever picking up a phone.

Any advancements in telematics technology will have one ultimate goal for fleet and equipment managers: less downtime. One thing that will never change is that the more downtime your equipment sees, the more money is hemorrhaged in both practical costs and time costs. Whether a long-haul truck, a crane, or a skid steer loader, uptime is critical because time is money.

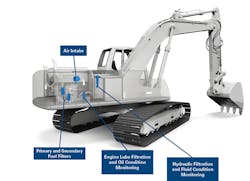

At Donaldson, we have technology that allows integrated data to be collected from all onboard systems—air, fuel, oil, and hydraulics—into a single fleet-management platform regardless of fleet or engine. This means that what could otherwise be an overwhelming amount of information can be put into action.

We predict that this idea will permeate into every aspect of telematics. This means more informed maintenance decisions, which means more uptime, which means more productivity. And more productivity is the ultimate goal.

Source: Donaldson