During World War II, the Austin-Western Road Machinery Co. developed the first hydraulic crane, the tractor-mounted Anteater, in response to the U.S. Navy’s need for a munitions-handling machine capable of working in tight quarters. The application of hydraulic technology to construction equipment was still in its infancy and hydraulic systems had only limited power, but soon after the war it was successfully applied to cranes for general service.

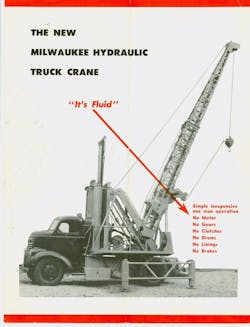

In 1946, Milwaukee Hydraulics Co. of Milwaukee, Wisconsin, introduced the first such crane. They called it simply the Hydraulic Truck Crane, for mounting on 1.5-ton highway trucks. It was powered by vee-belts from the truck’s power take-off, so it had no engine of its own; the truck was left running in idle to power the crane.

Sales literature touted its one-man, fluid operation. It had no gears or drums with their attendant clutches, linings, and brakes. Instead of drums, the cables were tied off with one passing through a horizontal sheave to swing and a second through vertical sheaves to control the hook.

Swing was powered by two long hydraulic cylinders set at an angle, one on each side of the circle; as one extended, the other retracted, taking the cable with it. The hook was raised and lowered by the vertical sheaves being hydraulically raised and lowered in a tower at the back of the crane. There was no need for an oiler; with all these works and bracing packed into a small machinery deck, there would have been no room for one.

It also had hydraulic outriggers to bear the entire weight of the crane when in operation. They extended to 11 feet, and the vertical legs were controlled independently. Along with all other crane functions, the outriggers were operated by a lever, and there were no pedals.

It was offered in capacities of 6, 10, and 20 tons at 8-foot radius, and custom models were offered for mounting on railroad cars, ships, barges, tractors, and more. The 6-ton boom telescoped from 19 to 32 feet, and booms to 60 feet were available for the larger models.

The crane had only 600 parts, with a mere 15 recommended for replacement due to wear. It had no cab, and could be equipped with a hydraulic clamshell bucket with 10 tons of digging pressure or a straight-boom, hydraulically assisted cable backhoe front without wrist action at the bucket.

By 1949, either the crane line or the entire Milwaukee Hydraulics organization was purchased by Bucyrus-Erie (B-E). B-E made major modifications to the design and initially offered only the 2-ton capacity H-2, then the 5-ton H-3. Optional cabs were made available.

The clamshell buckets, rated at 1/4 yard for the H-2 and 3/8 yard for the H-3, were continued. Over time grapples, tongs, a magnet, and clamshell buckets for light materials and trash basins were also offered. The backhoe front was modified with an extendable boom and fully hydraulic bucket, and a hydraulic shovel front capable of digging 12 feet 6 inches beneath the surface was also offered. B-E introduced the “Hydro-” terminology for each attachment, Hydrocrane, Hydrohoe, etc., with the H-2.

The 12-ton H-5 followed in the mid-1950s, and was offered with all three fronts. In 1956 or 1957, the H-3’s power train was changed to an onboard gas engine, which was standard for the H-5. In the spirit of the original crane from the 1940s, the H-5 was offered for mounting on a commercial truck, half-cab factory crane carrier, pedestal, or self-propelled chassis. Remote control of the truck from the crane was optional for some makes of trucks. The shovel and backhoe were discontinued in the 1960s.

B-E continued to offer the H-3 and H-5, with further modifications, as late as 1971.

The Historical Construction Equipment Association (HCEA) is a 501(c)3 non-profit organization dedicated to preserving the history of the construction, dredging and surface mining equipment industries. With over 3,800 members in twenty-five countries, our activities include publication of a quarterly educational magazine, Equipment Echoes, from which this article is adapted; operation of National Construction Equipment Museum and archives in Bowling Green, Ohio; and hosting an annual working exhibition of restored construction equipment. Our next International Convention and Old Equipment Exhibition will be September 16–18, 2022, at the National Construction Equipment Museum in Bowling Green, Ohio. Individual annual memberships are $35 within the U.S. We seek to develop relationships in the equipment manufacturing industry, and we offer a college scholarship for engineering and construction management students. Information is available at www.hcea.net, or by calling 419.352.5616 or emailing [email protected].