"Thumbs Up" for Cat's New E-Series

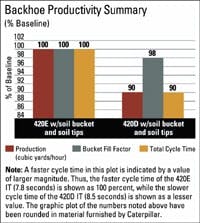

The results of a comparative study conducted by Caterpillar to determine the relative trenching performance of the 420D IT and 420E IT showed the new model to be approximately 11 percent more productive. The greater productivity of the 420E IT resulted from an approximate 9-percent advantage in cycle time and about a 2-percent advantage in its bucket-fill factor, which is the ratio of the bucket's capacity actually used, versus its rated capacity. Much of the 420E IT's production advantage likely results from its new flow-sharing valves, which apportion hydraulic flow more efficiently between backhoe functions.

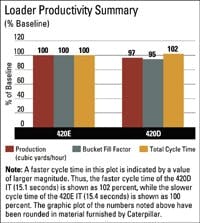

The results of a comparative study conducted by Caterpillar to determine the relative truck-loading performance of the 420D IT and 420E IT showed the predecessor model to have an approximate 2-percent advantage in cycle time (15.1 seconds, versus the 420E's 15.4 seconds). The new model, however, had a significant (5.5-percent) advantage in its bucket-fill factor, which is the ratio of the bucket's capacity actually used, versus its rated capacity. Thus, the net result in this comparison was an approximate 3.5-percent advantage in production for the 420E IT, compared to the 420D IT.

We asked Nick Krueger, a member of Caterpillar's backhoe-loader evaluation team, about the longer cycle time difference. In his opinion, changes in the torque-limiter system, which yield a more precise split of tractive effort and hydraulic power for the 420E, might trade a small amount of ground speed for overall better performance.

But a more likely reason, he says, were the perfect loading conditions at the site. When the operators were on the 420D, he says, ground conditions allowed them to start raising the boom while still backing away from the pile — in order to have the bucket at dumping height when reaching the truck. But if the ground had been soft underfoot or rough, he says, chances are that the boom could not have been comfortably raised while backing from the pile. This would have meant that the operators probably would have had to disconnect (neutralize) the transmission, somewhere in the cycle, to gain time for boom raise —thus adding to cycle time. But the 420E IT, with faster boom raise, did require use of the neutralizer function.

Miller: "The quickness of the loader-boom lift lets you run a tighter cycle. With the D-Series, you'd have to neutralize somewhere in the cycle to allow time for boom lift, so cycles couldn't be as tight.

Maas: "The flow-sharing valves give the stick a lot more power and speed. Stick performance is far superior on the E-Series, compared to the D, and it makes trenching much more efficient overall."

Miller: "The E-Series backhoe has more power closer to the tractor. You can work closer to the machine, and this is an advantage in tight-quarter digging."

Maas: "The E-Series has a dual torque-limiter setting that makes truck-loading superior over the D. It starts in low torque, then shifts to high. There's less tendency to stall, and the system gets the bucket up more efficiently."

Miller: "I like the flatter floor of the new multi-purpose bucket. It's easier to load."

Maas: "The boom is usually the weak link in lifting, but the new lock is built to take the lifting stress."

When Curt Maas clamped an immense log — about 18 feet long and 20 inches in diameter — between the backhoe bucket and the hydraulic thumb of a new Cat 420E IT, we had just the fleeting thought that maybe he was kidding. The log seemed to us an impossible load for the machine. But the new Caterpillar made the lift, swung side-to-side with the log in an iron grip, and all the while, as far as we could tell, remained completely stable.

Maas, a test operator at Caterpillar's Peoria (Ill.) Proving Ground (PPG), spent a couple of days with Construction Equipment this past November, along with fellow operator Norm Miller, demonstrating the capabilities and features of the new 420E IT as representative of the company's new E-Series backhoe-loader range. The lineup includes the 416E, 420E and 430E — with the latter two models also available with an integrated-tool-carrier (IT) front end. Standard digging depths are, respectively, 14.3, 14.3 and 15.4 feet.

The E-Series models, which replace the D-Series machines launched in late 2000, have quite a long list of design changes, compared with their predecessors and, according to Caterpillar, are also more productive at basic earthmoving tasks. The company put numbers to these stated productivity increases by sharing with CE the results of a recent PPG comparison between the 420E IT and its 420D IT predecessor.

During our visit to PPG, operators Maas and Miller, along with the PPG backhoe-loader evaluation staff — Brad Holsapple, Gerry Stewart, Nick Krueger and Elizabeth Baldwin — demonstrated the methodology Caterpillar employs in its comparative testing. They arranged for us to observe the machines running side-by-side in trenching and truck-loading operations, while Krueger and Baldwin electronically recorded machine performance.

The electronic test-data-collection system the company uses is a computer-based process that allows every cycle of a test machine to be divided into its primary segments for later analysis. During the trenching comparison, for example, times are recorded for digging, swinging/dumping and returning, as well as for time spent repositioning.

To complement this look at the comparative performance of the new model and its predecessor, senior project engineer Jim Joy, from Caterpillar's Building Construction Products Division in Clayton, N.C., met us at the Peoria Proving Ground to explain the details of the new E-Series design.

Structurally, the design enhancements of the E-Series, compared with the D-Series, go right to the very backbone of the new machines — the mainframe, which has been modified significantly in four key areas: loader tower, front and rear axle mounts and swing post. According to Caterpillar, these mainframe changes further complement the already-high-strength design of D-Series models. Structural changes at the loader end of the machine include boom arms with a beefier box-section and a heavier torque tube that provides added rigidity to the assembly.

At the backhoe end, the boom has been modified, says Caterpillar, to reduce stress points in heavy-duty applications. Specific changes include one-piece side plates, versus fabricated side plates, larger mounting pins, and the addition of a replaceable wear pad to protect the boom underside from contact with work tools. Another significant change involves the boom nose, which has been reconfigured and strengthened to accommodate a new extendible stick. The boom lock has been redesigned, too, not only to keep the backhoe tighter during transport, but also to more effectively handle the stress of lifting with the stick when the boom is in its locked position.

The new extendible stick is a significant development for the E-Series, says Joy, and has been designed with an "outside slider" configuration. This means, he says, that the outer structure of the stick extends by sliding over a stationary inner structure. By comparison, the D-Series extendible stick pushed out an inner structure from within a stationary outer structure. And to maintain proper fit between the two sections, the new extendible stick incorporates a redesigned system of greaseless wear pads that can be adjusted in about 30 minutes, according to Caterpillar, compared with two hours on D-Series models.

Two rows of serrated gripping teeth on the bottom surface of the new extendible stick's sliding section allow the operator to clamp material securely between the bucket and the stick without risking damage to the stick. But as handy as the gripping teeth might be, they can't match the heavy-duty clamping power and dexterity of an E-Series extendible stick equipped with a hydraulic thumb.

Although the thumb is optional, all E-Series backhoe sticks, whether extendible or standard, are fitted with thumb and thumb-cylinder mounts to allow bolting on the attachment. (The D-Series could use a thumb only with a standard stick.) A thumb-plumbing kit allows quick installation of the attachment, a process facilitated if the machine is equipped with a six-function main valve from the factory.

In concept, the design of the closed-center, load-sensing, 43-gpm hydraulic system used in the E-Series is essentially the same as that for the D-Series. But, that said, the E-Series incorporates a number of refinements, among them an increase in main-relief pressure to 3,600 psi, up from 3,300 psi in the D-Series.

While the pressure increase results in more available hydraulic horsepower at both the backhoe and loader ends, the new hydraulic system also incorporates features that contribute to easier operation. New thumb wheels near the top of the backhoe joysticks, for example, allow easy control of auxiliary functions — such as the extendible stick and thumb. These controllers replace floor-mounted pedals in D-Series machines and are designed to provide low-effort, precise, proportional control of auxiliary functions — while also providing more foot room for the operator.

Also contributing to ease of operation are the new flow-sharing valves, which automatically proportion hydraulic flow between the boom and stick or between the boom and swing functions to more exactly match the operator's intentions. In essence, says Joy, the flow-sharing valves make multiple-function operation easier to control, which helps less-experienced operators maintain acceptable production rates, and offers experienced operators more precise control and the prospect of higher production.

Caterpillar backhoe-loaders have long used the company's "torque-limiter control," which is basically a system that manages the distribution of engine power between the hydraulic system and the drive train. According to Joy, refinements in this system result not only in enhanced loader performance through a more precise split of engine power between the hydraulic system and drive wheels, but also in a more aggressive backhoe by assuring that maximum engine power is used to develop hydraulic flow.

The operator's station for E-Series models has been completely redesigned, featuring a new four-post ROPS configuration that provides more interior space than the ROPS configuration for the D-Series. Overall, improvements to fit and finish in the new cab further contribute an automotive-type environment, which was already apparent on D-Series models.

For E-Series models, the front console has been made narrower to provide enhanced visibility to the loader bucket, and a hood that is lower by 3.5 inches at the cowl further improves visibility. The right-side console has been made more compact, further enlarging interior space, and a foot pedal controller for the tilt steering wheel makes the spin from loader to backhoe positions that much easier.

A significant change for E-Series models is the in-cab switch for easily changing the digging pattern between hydraulic-excavator and backhoe-loader configurations. A two-position electrical switch on the left console allows the selection. By contrast, D-series models had a pattern-changer control on the left side of the machine's frame, behind the rear tire — obviously not as handy as the E-Series design.

Another cab enhancement of note is the increased performance of the optional air-conditioning system. A larger compressor, 20-percent increase in airflow, and repositioned vents go a long way toward increased operator comfort, says Caterpillar. In addition, the air-conditioning system incorporates easier-accessed filter locations, one in the right inner fender and one in the right console. Both can be cleaned with compressed air.

Combine the amenities of the new E-Series cab with Caterpillar's fresh design for basic structures, hydraulics, power train and utility-enhancing features (like the new extendible stick and hydraulic thumb), and the result is a solid new E-Series platform that should serve the company long and well.