- Allied Construction Products

- Stanley

- Ingersoll Rand

- Okada America

- Huskie

- Atlas Copco

- Kent

- Arrowhead

- NPK

- MKB

- Indeco

- BTI

- Bobcat

- Caterpillar

- Basic design considerations

- Powering the piston

- Technology enhancements

- Breaker Specifications (Ranges for Impact Energy Class and Working Weight)

- Average List prices and Hourly Rates

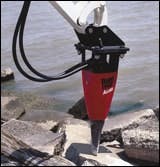

Considering all the tough jobs that mounted hydraulic breakers can take on, it's no wonder why these powerful tools are so popular. Chores range from demolishing buildings, to removing cracked sidewalks; from trenching in rock, to breaking frozen ground for utility repairs; and from secondary reduction of blasted material in quarries, to selectively uncovering pockets of ore in large mines.

Unofficial estimates place North America's current annual mounted-breaker market between 10,000 and 15,000 units — a market shared by a multitude of brand names. Many of the familiar names, however, are the result of private-labeling agreements in which, for example, an excavator or skid-steer-loader manufacturer places its own brand on products purchased from a breaker manufacturer.

Peter Bigwood, president of Atlas Copco Construction Tools, sees smaller breakers as becoming increasingly private-label commodities. And in North America, he says, smaller breakers also are beginning to supplant hand-held tools, but not yet to the extent that this trend has taken hold in Europe and Asia.

Other trends Bigwood observes include the expanded use of quieter breaker models, especially for reclaiming demolition debris on site; the use of larger models in quarries as the use of explosives becomes more regulated; and, overall, a move toward breaker designs aimed at protecting these tools from on-site hazards, including the inexperienced operator.

Mounted hydraulic breakers reflect two basic exterior designs — "side-plate" and "boxed" — the latter sometimes also identified as "enclosed" or "full-cradle." The side-plate design essentially uses two slabs of steel that typically are secured to the sides of the breaker with threaded fasteners, an arrangement that usually leaves the front and back of the breaker open.

According to Al Springer, national sales manager for Allied Construction Products, advantages for side-plate breakers include a simpler, often-less-expensive design, cooler operation and reduced operating weight. On the minus side, says Springer, these breakers are louder (than their boxed counterparts), side bolts can loosen or break, and the plates do not afford as much protection as do boxed designs.

Boxed breakers use an outer housing that completely surrounds the breaker mechanism, which normally is positioned in the housing with blocks of resilient material that buffer the breaker from the housing and create a shock-absorbing barrier at the top, where the breaker mounts to the carrier. Advantages for the boxed design, says Springer, include more protection from jobsite debris, quieter operation, reduction of shock and vibration transmitted to the carrier (thanks to the resilient upper mounting), and no problems with plate-mounting bolts.

Mounted hydraulic breakers also can be classified by the principal means they use to "fire" (force down) the piston, which strikes the breaker's working tool that actually engages the material to be broken. In today's market, you'll find three basic piston-firing systems: nitrogen-gas only, hydraulic-oil only, and a combination of nitrogen gas and hydraulic oil. All three designs, however, use hydraulic oil from the carrier to raise the piston to its firing position.

As the piston in a nitrogen-fired breaker is forced upward, it compresses the gas charge above it. When hydraulic pressure below the piston is released, the compressed nitrogen forces the piston down. A major advantage of the gas-only breaker, says Chuck Stevens, senior vice president of sales for NPK, is the capacity of the nitrogen charge "to keep up with the velocity of the piston." According to Stevens, the gas-only design is simple, easy to service, and requires little maintenance, other than periodically checking the nitrogen charge.

Oil-fired breakers, on the other hand, rely principally on pressurized hydraulic oil from the carrier to force down the piston. This design, however, typically also employs an enclosed nitrogen charge that serves as a shock absorber for the hydraulics, according to Tom Pinchuk, attachments marketing manager for Ingersoll Rand. This "energy chamber," as Ingersoll Rand calls the area containing the nitrogen charge, accepts oil displaced from the top of the piston as it moves upward to its firing position.

When the piston fires, pressurized oil from the carrier forces the piston down. Near the end of its stroke, however, the piston is moving so fast that flow from the carrier may not keep pace. To avoid cavitation, the energy chamber releases additional oil to supplement flow from the carrier. According to Pinchuk, since the "fully hydraulic" breaker does not principally nor directly rely on compressed nitrogen gas to generate blow energy, the breaker strikes with constant maximum force, regardless of nitrogen pressure.

The oil/gas-combination breaker uses both nitrogen and hydraulic oil as principal firing means. Nitrogen in a sealed chamber at the top of the piston is compressed as the piston is lifted. When the compressed nitrogen fires and forces the piston down, the nitrogen's effort is assisted by the carrier's pressurized hydraulic oil, which typically is forced into an annular space around the piston and adds energy to the descending piston. Some combination breakers can derive as much as 75 percent of their piston-firing power from the nitrogen charge.

Allied's Springer brings a sense of perspective to the various designs:

"Manufacturers frequently are asked what breaker design is best," says Springer. "We as manufacturers have our biases, of course, but all three designs have plus and minus points. All three are good, or they wouldn't persist in the marketplace."

Among the most potentially damaging events in a breaker's life is "blank firing," that is, when the piston slams down to the bottom of its stroke without contacting the tool, thus forcing the breaker to absorb tremendous energy. To lessen the effect of blank firing, some breaker designs incorporate a hydraulic cushion at the end of the piston's stroke. Other designs prevent the breaker from firing if insufficient resistance (or preload) is sensed at the working surface.

Yet other designs, such as that reflected in the Allied Rammer m-Series and in certain larger Atlas Copco models, allow the breaker, in the hands of an experienced operator, to be adjusted to suit the application. The breaker can be made either to shut off automatically when preload diminishes to an undesirable degree or, conversely, to begin operating with no preload to facilitate working in difficult horizontal or overhead positions.

A number of today's breakers also feature the capability to automatically adjust the ratio of impact energy to impact rate to suit the material being broken. Breakers typically are more efficient in hard materials, for example, when working at maximum blow energy, but at reduced blow frequency. In softer materials, reversing this ratio normally results in the greatest efficiency. The potential benefits of being able to adjust these parameters, says Ingersoll Rand's Pinchuk, include improved production, reduced fuel consumption and less carrier wear.

To complement the piston's percussive force when working in particularly tough material, some larger breakers can recover recoil energy by using it to force hydraulic oil into an accumulator, which then adds the force of this oil to the next blow. Some manufacturers claim energy boosts of up to 25 percent.

Jobsite conditions that can quickly shorten breaker life are insufficient lubrication of the working tool and abrasive dust that works its way into the lower portion of the breaker. Thus, more breaker models are being fitted with automatic lubrication systems. And for breakers at work in extremely dusty and abrasive applications, a sealing system (usually an option) often can be installed at the tool/housing interface to prevent intrusion of damaging debris.

Also high on the list of technical advances is easier maintenance and overhaul. Increasingly, more breakers are being designed to allow easier changes of the lower bushing and working-tool — sometimes even in the field and without removing the breaker from the carrier. And in a growing number of instances, easier routine maintenance is complemented by new designs that require far less time to overhaul, compared to predecessor models.

And in all of this, as Tom Pinchuk reminds us, advances in metallurgy also have greatly enhanced the overall performance and durability of the mounted hydraulic breaker.

| Web Resources | ||

| Allied: www.alliedcp.com | Arrowhead Rockdrill: www.arrowheadrockdrill.co.uk | |

| Atlas Copco: www.atlascopco.com | Huskie Hammer: www.huskiehamer.com | |

| Indeco: www.indeco-breakers.com | BTI: www.rockbreaker.com | |

| Ingersoll Rand: www.irco.com | Kent: www.kentdemolition.com | |

| Dominion Equipment Parts: www.dominionequipmentparts.com | NPK: www.npkce.com | |

| Okada: www.okadaamerica.com | Stanley: www.stanley-hydraulic-tools.com | |