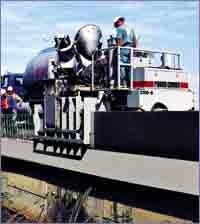

LeeBoy purchased manufacturing rights to add the first concrete machine, the 7,000-pound LBC-24W, to its product line. The heaviest of the trimmerless machines, it uses a blade and auger in front of the mold to touch up the subgrade.

- Average Curb-and-Gutter Machine Costs

- Curb-and-Gutter Machine Specs (by weight)

- GOMACO

- Messinger

- Leeboy

- Power Curbers

- M-B-W

- Miller Formless

- Miller Spreader

- Huron

Grade-control technologies used to guide bulldozer and motor-grader blades to within fractions of an inch of design specifications are changing the curb-and-gutter-machine market both directly and indirectly. Stringless systems for grade control have been adapted to guide steering and elevation on high-production trim-and-pour machines. Less directly, though, electronic grade controls have so improved earthmovers' finishing ability that low-cost machines without grade trimmers can place curb, gutter and sidewalk on a wider range of projects.

"Increased acceptance of excavating technology has enhanced the ability of the excavator to hold the grade within tolerance. This has opened the market for light weight, smaller slipform machines," says Frederick Russell, product manager for Miller Spreader, whose largest machine is 4,800 pounds and trimmerless. "This technology (precise grade control) has allowed the small contractor to diversify and not have to subcontract a lot of concrete work that was previously hand formed or required a ground-engaging machine."

A contractor who uses electronic controls on a grader or dozer to produce grades that are ready to accept curbing may not need a curb-and-gutter machine with a trimmer on some jobs. It's unlikely that they can replace trim-and-pour machines on high-volume jobs, but mid-sized machines that place curb and gutter on grade can be more competitive on more projects than before thanks to precision earthmovers.

Manufacturers who focus on mid-sized machines such as M-B-W, Messinger, and newcomer LeeBoy, mention the low entry cost of their machines as advantages. In fact, list prices on the heaviest of the mid-sized machines (5,000 to 10,000 pounds) are $20,000 to $40,000 less than the smallest machines available with trimmers. Adding to their economy is the fact that mid-sized machines can be trailered behind a medium-duty truck.

Opportunities in mid-sized curb-and-gutter machines drew LeeBoy into the market for the first time last year and enticed Messinger to add the 5,000-pound CF5000 to its line, smack in the middle of the mid-sized competition. The 7,000-pound LBC-24W is the first concrete machine in the LeeBoy line, and it's there to offer buyers of LeeBoy commercial asphalt pavers a tool they can use to wrestle profit and schedule control away from curb-and-gutter subcontractors.

There's a sharp philosophical divide among manufacturers over the utility of mid-size curbers. For example, names such as GOMACO and Power Curbers that make both trim-and-pour machines and small extruders offer no models in the 3,000- to 10,000-pound range. In fact, over the past 36 months, Power Curbers has eliminated two machines, leaving no models between the 1,200-pound 440-XL extruder to the 23,500-pound 5700-Super-B.

There's a clear difference between the two styles of machine, exemplified by a jump in horsepower from less than 40 for the largest mid-sized machine to 92 horses in the smallest machine with a trimmer. And the vast majority of trim-and-pour machines run on a crawler undercarriage. (Huron does field something of a hybrid¡ªthe 80-horsepower 650B on tires is available with an optional trimmer. Huron's 21,000-pound 880 with standard trimmer also rides on rubber.)

Size does, inevitably, matter as curbing projects grow in complexity. Mid-sized curb-and-gutter placers rapidly lose their economic advantage on projects where earthmovers can't produce precise grades cost effectively. And when the contractor wants a curb machine that can also pave seven or eight feet wide, there's little alternative but to step up to the heavier machines (bolt-on extensions can stretch the largest curb-and-gutter machines to slipform pavements as wide as 20 feet).

Versatility of the larger machines promises a higher level of usage for contractors with an eye for a variety of concrete work, and more hours of use quickly overcomes the higher entry cost. And there's a choice of ten models on the market at reasonably easy-to-transport weights of less than 24,000 pounds.

Power Curbers may have felt competitive pressure on the 5700-B from mid-size machines, but it's far more likely that there simply were challenges to marketing a 23,500-pound, trim-and-pour machine with just 84.5 horsepower. Last year, Power Curbers dropped a 133-hp Deutz diesel into the renamed 5700-Super-B, boosting it solidly into the power range with other 23,000-pound units (a niche also occupied by GOMACO and Huron).

Beyond their advantages in terms of brute specifications, though, many larger curb-and-gutter pavers are also increasing sophistication in the area of electronic controls that promises to reduce labor and on-site logistics costs. One example is the All-Track Steering and All-Track Positioning designs built into GOMACO's GT-3600, GT-6300, and Commander III. The feature allows operators to choose from five steering modes. The machines' steering circuits, indeed all of their hydraulic circuits, use electronic-over-hydraulic control. They're coordinated by the machine's main computer. Crab Steering improves approaches and speeds the process of orienting the machine to the stringline. GOMACO says the GT-3600, for example, can reverse steer on-line to within 1/8-inch tolerance.

GOMACO designed its grade and steering controls to automatically adjust trajectory in and out of a tight radius. Machines are equipped with three sensors. One is located at the front of the mold; the second at the front of the stainless; and the third is aligned with the back of the stainless. As the GT-3600 enters a radius, the operator switches from sensor 1 to sensor 2 with a toggle switch.

The Power Curbers 5700-SUPER-B offers optional digital network controls. Its network offers what Power Curbers calls Slope Compensation, which automatically adjusts grade elevation and steering alignment to maintain a consistent top and back of curb in transitions between catch curbing and spill curbing. The system is also designed to automatically correct curb elevation to compensate for machine movement when pouring from a banked road surface.

GOMACO demonstrates its commitment to advancing the application of digital technology in the curb-and-gutter market by installing its G21 networked control system on most of its trim-and-pour machines. The system connects electronic components from all over the machine so they can communicate using what's called a CAN (controller area network) bus.

Computer-network architecture enhances a control system's ability to communicate with external computer systems. It allows the curb machine's controller to interface with stringless grade-control technologies such as lasers. The network also facilitates use of software to automate elevation and steering corrections in transitions without stringline adjustments.

The G21 network allows GOMACO machines to pour curb guided by robotic total stations and three-dimensional control systems rather than a stringline. Total stations on the job site are oriented to the site plan using surveyors' reference points. The three-dimensional system's command center is mounted on the paver and connected to the CAN bus, and the three-dimensional model of the project is downloaded into the command center. The total stations fix the mold's position on the project plan with laser shots to prisms mounted on the paver.

As the machine moves, the total stations track it and send radio signals back and forth to the command center as frequently as eight times per second. The command center compares the paver's real-time coordinates to the design plan and communicates with the G21 controller, telling it how to guide and steer the paver.

"The No. 1 advantage is going to be the jobsite logistics. Contractors will be able to move their equipment around the site without having to worry about running over the stringline," says Kevin Klein, GOMACO research and development manager. "The systems have already proven to be as accurate and give a better performance than what a stringline job would."

The curb-and-gutter-machine market remains in transition to digital controls and the higher reaches of automation. There are still plenty of options for buyers who prefer analog controls. Power Curbers continues to build the 5700-Super-B with analog control systems standard, choosing to make network controls an option. Electronic grade controls are pushing the curb-and-gutter market to new levels of productivity and quality whether they're mounted on the machines or the earthmovers that work just ahead of them.

| Web Resources | ||

| GOMACO www.gomaco.com |

||

| Huron www.huronmanufacturing.com |

LeeBoy www.leeboy.com |

|

| M-B-W www.mbw.com |

Messinger www.messingerinc.net |

|

| Miller Formless www.millerformless.com |

Miller Spreader www.millerspreader.com |

|

| Power Curbers www.powercurbers.com |

||