- Skid-steer meets wheel loader

- Vertical lift plus longer wheelbase

- Production gains

- New entries

- Basic Specifications: Largest Skid-Steer Loaders

- Mustang

- Komatsu

- Bobcat

- New Holland Construction

- John Deere

- Daewoo

- Gehl

- Caterpillar

- Volvo

- Case

- Thomas

- JCB

Once considered utility machines, skid-steer loaders continue to grow in size. Not too long ago, the top operating capacity classification was 1,350 pounds and above. Size classes now run up to 2,701 pounds and higher. Five manufacturers offer skid-steers with operating capacities exceeding 3,000 pounds¡ªand the size of these machines is expected to continue to grow.

The new crop of large skid-steers is intended to meet the growing demand for more power and productivity. Many skid-steer buyers use their machines much as one would use a wheel loader¡ªloading trucks, excavating and material handling. Breakout force is now an important specification, whereas skid-steer loaders traditionally have been thought of as too light for heavier excavating. When owners buy a new skid-steer loader, they tend to move up in size.

Skid-steer loaders also have become, in a sense, power units for attachments. The number of skid-steer attachments is considerable, and the larger loaders can handle truly heavy-duty attachments that run from the skid-steer's hydraulic power source. Most large skid-steers have high-flow hydraulics either as an option or as standard equipment. As models grow in size and power, so will the attachments designed for them, providing high productivity on large, heavy-duty jobs.

As skid-steers grow larger, they're being equipped with features typically reserved for machines such as wheel loaders. Cabs are being made larger with more operator amenities. Dump heights are increasing and more skid-steers are being equipped with vertical lift systems that keep the implement on a vertical path as it's lifted, providing greater vertical reach. Hydraulics get a boost and drive trains are being beefed up.

A major attraction of skid-steer loaders is the price. They still remain a good value. The largest loaders average around $29,000, with the biggest machines priced at about $48,000. A compact wheel loader carries an average price tag of more than $60,000, although the smallest wheel loaders are priced competitively with the largest skid-steers. Along with an attractive price, big skid-steers retain a simplicity that provides for easy and quick service. Cabs lift to reveal hydraulic components. Rear compartments open wide and radiators swing out to expose the engine and filters.

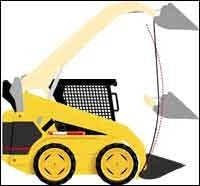

A major feature of many of the larger skid-steers is vertical lift. Typically, when the loader arms lift the implement, it would raise in an arc or radius. As it reached full height, the implement's reach would have diminished, restricting the skid-steer's ability to load or place materials. By modifying the loader arm linkage so that the implement elevates in a straight line vertically, the skid-steer can achieve greater reach and lift, giving the larger skid-steer loaders the ability to load trucks with higher sideboards or place palletized materials at higher elevations.

Vertical lift plus longer wheelbase

Bobcat teams the vertical-lift feature with a longer wheelbase to provide not only greater reach and lift height, but also improved speed and capacity. The largest Bobcat skid-steer in the line, the S300, checks in with a rated operating capacity of 3,000 pounds. Similar to Bobcat's next largest machine, the S250 with a 2,500-pound operating capacity, the S300 nevertheless outweighs the S250 by 417 pounds and has a more powerful engine at 81 horsepower vs. 75 horsepower. A high-flow auxiliary option package gives the S300 an additional 10 gpm of flow, for a total of 30.7 gpm and 3,300-psi system pressure.

When Case introduced its XT line of heavy-duty skid-steers, it drew a lot of attention because of the machines' size and power. Today, the line has been fleshed out, with the largest remaining the 95XT at 3,150 pounds operating capacity. Add a counterweight and the figure jumps to 3,650 pounds. Joining the 95XT is the 90XT at 2,450 pounds operating capacity and the 85XT at 2,400 pounds, rounding out the largest three skid-steer loaders available from Case. Both the 90XT and 85XT can boost their operating capacity by about 16 percent with counterweights.

Since their introduction, these machines have seen some enhancements, including an optional ECI proportional fan drive that reduces operating noise in normal conditions, delivers more power, boosts fuel efficiency, and provides a warm operator's compartment. The ECI fan drive runs at low revolutions during normal operations but switches to full speed when extra cooling is needed. All units can be equipped with optional high-flow hydraulics with flows up to 40 gpm. The 90XT and 95XT can be equipped with 5,000-psi hydrostatic high-flow hydraulics for greater performance with high-production attachments. Any of the large XT skid-steers also can be equipped with optional ride control for a smoother ride and less material spillage. Ride control acts like a shock absorber by cushioning loader arms from the jolts of rough terrain.

Also topping the 3,000-pound operating capacity is the John Deere 280. With an operating capacity of 3,200 pounds, this big machine has a vertical-lift system with cushioned boom cylinders, giving it a lift height of 10 feet 7 inches and a dump reach of 39 inches when fitted with the construction bucket.

The 280 has servo-controlled low-effort steering levers, while the rest of the line has manual controls. The steering system has been improved, giving it the ability to maintain its adjustment for a longer time. An optional two-speed transmission is offered, providing ground speed up to 12 mph. Also optional are the high-flow hydraulics, raising the flow from the standard 28 gpm to 41.5 gpm.

Rounding out the more-than-3,000-pound operating capacity skid-steers are the Gehl 7800 and 7600 and the Mustang 2105 and 2095. The four models share operating capacities of 3,600 pounds and 3,150 pounds, making the 7800 and 2105 the largest skid-steer loaders in terms of operating capacity.

Back in 2001, Construction Equipment field tested the then-new Gehl 7800 and 7600. We noted at that time the production gains posted by the 7800 and 7600, relative to their smaller counterparts, basically increased in proportion to the difficulty of the application. We also noted that the two Gehl machines were essentially identical, except that the 7800 had a turbocharged engine, high-flow hydraulics and two-speed drive. We were also struck by the large size of the drive pumps and motors.

Both the Gehl and Mustang machines are nearly identical, which is not a coincidence because Mustang is owned by Gehl. The Gehl models outweigh the Mustangs and Gehl offers three choices of operating control setups, with Mustang's big machine offering a hands-only control option.

Those interested in the Mustang skid-steers will find that all the larger models, including the new 2044, 2054, 2064 and 2074, have cabs that are roomy and well designed for operator comfort. The 2044 and 2054 have three control options, and the 2064 and 2074 have two control options. Integrated into these controls are switches that operate the two-speed drive, auxiliary hydraulics and horn. The 2064 and 2074 also have servo-controlled hydrostatic transmissions, easing operation.

Just below the 3,000-pound class is New Holland Construction's LS190. Rated at 2,800 pounds, it features the third-generation Superboom vertical lift. This combines with a low center of gravity and long wheelbase for stability, more lift-and-load carrying capacity and a smoother ride. An ergonomically designed operator's compartment offers a wide entry and plenty of room inside. Also included are low-effort, self-neutralizing hand controls and responsive foot controls. The instrument panel, located overhead, lets the operator monitor all machine functions.

Several machines are available in the 2,200- to 2,700-pound operating capacity class.

Caterpillar's largest skid-steer loader, the 262, has a rated operating capacity of 2,500 pounds. It has a wheelbase of 48.3 inches, providing an increased load-carrying capability and a smooth ride. The Cat vertical linkage design results in a comparatively lightweight structure given its load-carrying capability and allows the machine to stand up to heavy digging with minimal linkage wear.

Other features of the 262 and its companion, the 252, include low-effort pilot-operated hydraulics, an anti-stall feature that helps with digging performance, easy serviceability and convenient service checkpoints.

At 2,425 pounds operating capacity, JCB's largest unit is the 1110 Robot. It, along with the 190 Robot, represent increases in operating capacities over their predecessors, the 185 and 1105 Robots. Both new machines have a main hydrostatic drive pump plus a dedicated loader and attachments supply pump with a flow of 20 gpm. Control patterns can be specified, with either the popular manual hand-only or manual hand and foot controls. Alternately, full servo control joysticks are offered as well.

JCB models are the only skid-steers available with a single loader arm with a side-entry cab. JCB says that this design is safer and provides a better view from the operator's compartment.

Checking in with an operating capacity of 2,400 pounds is the 245 from Thomas Equipment. Starting off with an 87-hp engine, power is transferred from the engine to hydrostatic pumps through a direct coupling, sparing the need for regular adjustments or servicing. Thomas emphasizes the toughness of its machines, noting the thickness of the steel, the 6,970 pounds of breakout force, and thick loader arms. All this beefiness pushes the operating weight of the 245 to 8,000 pounds.

Daewoo's three largest skid-steers are the 2060XL, 1760XL and 1550XL, with operating capacities of 2,000 pounds and 1,500 pounds. All can be ordered with high-flow hydraulics. To protect the bucket cylinders during rough jobs, the cylinders are inline with the boom and protected from debris coming over the top of the bucket. Likewise, no hydraulic lines are exposed on the boom arms, all being routed inside the boom but with easy access.

The newest entry into the skid-steer loader market is Komatsu, with the introduction of the SK714 and SK815. The SK815 has an operating capacity of 1,550 pounds and is being touted by Komatsu for its Automatic Power Control (APC). APC is a feature of the hydraulic system designed to allow full utilization of engine power, without overload, on tough jobs. The operator can work with full power on any phase of the job without worrying about engine stall out. In addition, both machines have proportional control joysticks and Komatsu's HydrauMind hydraulic system that lets the operator monitor machine performance.

Next month, Volvo plans to unveil its skid-steer loader line to the North American market. Although details are still coming in at this point, the line will consist of five models, with all five machines having operating capacities at and above 1,350 pounds. The largest unit will be the MC 110 at 86 horsepower and 2,450 pounds capacity.

| Web Resources | ||

| Bobcat www.bobcat.com |

||

| Case www.casece.com |

Caterpillar www.cat.com |

|

| Daewoo www.dhiac.com |

Gehl www.gehl.com |

|

| JCB www.jcb.com |

John Deere www.johndeere.com |

|

| Komatsu www.komatsuamerica.com |

New Holland www.newholland.com/construction |

|

| Mustang www.mustangmfg.com |

Thomas www.thomasloaders.com |

|

| Volvo www.volvoce.com |

||