Steep hourly cost makes operating efficiently more important to crawler dozers than most other construction equipment. The cost is largely associated with undercarriage wear, so the best bulldozer operators make every move count whether they're doing production earthmoving, finishing or clearing land.

Some of the best ideas for improving dozer productivity defy operators' assumptions.

"A lot of operators who are doing production dozing think they should make long cuts. They want to see dirt boil or roll in front of the blade," says Brad Van De Veer, senior product consultant at Caterpillar's Edwards Demonstration/Application Center. "In reality, the blade will only hold so much dirt. Once it's full, you start losing dirt off both sides of the blade, leaving windrows that will have to be moved again. It wastes horsepower and fuel, and it can cause track slip and undercarriage wear.

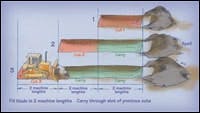

"You should be able to get a full load on the blade in two lengths of the tractor at the most — and that applies to any size tractor. Once the blade is full, you stop cutting and slide the dirt in front of the blade."

Short, aggressive cuts set up what is perhaps the most energy-saving way to doze dirt — what Caterpillar calls "front-to-back or slot dozing."

"You start one to two tractor lengths back from where you're going to move the dirt, instead of on the opposite side of the field," says Van De Veer. "Fill the blade and start a pile or fill the area."

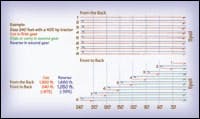

The next step is to back up one to two tractor lengths behind the start of the first cut, fill the blade, and slide the load, or carry it, through the slot created by the first pass and deposit it on the spoil pile. Use first gear to aggressively fill the blade. In small and medium sized tractors, shift up to second when sliding the load. Repeat the process, sliding a full blade load through the slot further with each pass.

Working in the slot increases blade load by as much as 30 percent and prevents material from falling from the blade.

Front-to-back dozing cuts undercarriage costs. Instead of backing the entire length of the cut after each push, you only reverse the tractor the distance of the previous push plus one or two tractor lengths.

"Running in reverse causes the most undercarriage wear, and it's the most unproductive time in the work cycle," says Van De Veer. "Working front to back, you reduce the amount of reverse operation, which decreases operating costs and increases productivity."

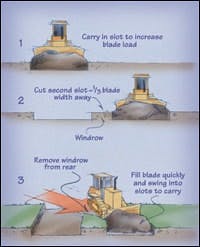

Van De Veer says slots can be dug as deep as the blade is high.

After the first slot is completed, back up to about two tractor lengths from the spoil and move over, leaving about one-third of a blade width between the edge of the blade and the first slot. This berm will hold material in front of the blade on the second slot.

After the slots are cut to the desired grade, the work pattern reverses for clearing the berms.

"You want to work from the rear of the cut, or the opposite end from the spoil, rather than front to back," says Van De Veer. "Load up the blade quickly, and use blade tilt to steer into one of the slots to carry the load to the pile or fill."

A criss-cross pattern will help keep the cut level: If you slide the load up the left slot on the first pass, swing into the right slot on the second pass, and then back to the left slot on the third.

Some simple techniques will make fine grading more efficient, too.

A videotape called Tips From the Pros: Crawler Dozer from VISTA Start Smart Training recommends: "When finishing or dressing, working with a partially loaded blade is better than working with an empty one. It smoothes out the ride and distributes fines across the blade.

Load only half of the blade to keep windrows on one side of the machine. The blade can overlap previous passes to act as a depth guide.

"The smoothest finishing jobs happen when dirt is worked from at least two different directions [passes oriented at 45- to 90-degree angles to each other]," according to VISTA. "It's the same principle as an orbital sander on wood. Irregularities get smoothed out if attacked from more than one direction."

Van De Veer adds a special reminder to stay alert when finishing.

"When you're finish dozing, you usually have grade checkers or other laborers on the ground, you're working in a confined area with grade stakes, and maybe curb and gutter or drain tile. You can get pretty focused on the blade and the job in front of you, but you have to pay attention behind when backing up."

A crawler dozer's basic design makes the machine a prime candidate for working where other machines fear to tread. They're not immune to danger, though.

"Low center of gravity and power in the tracks make crawler dozers excel in slope work — working in areas that other machines can't or shouldn't touch," says VISTA's Tips videotape. "But know your machine's limits. Rollovers are a leading cause of injuries and fatalities."

Caterpillar's equipment-training program for crawler dozers admonishes operators to work more slowly on slopes, keep attachments low, and work up and down slopes if possible.

"Don't think you can jump clear of a tumbling machine," warns VISTA. "Always wear your safety belt and make sure the ROPS is in good condition.

"When pushing dirt off a high wall or a steep slope, don't push each load over the edge," the Tips video recommends. "Leave one blade load at the edge to act as a stop. Let the second blade-full push the first one over the edge. This keeps your machine back away from danger."

When you're working down a slope, remember that gravity can be your friend.

"Pile several loads at the brink of the hill, then push them down the hill in one pass," VISTA recommends. "You'll be able to move more material.

"Keep the machine under control at all times. Many newer machines have hydrostatic transmissions with automatic holdback. But on machines with torque converters, never coast downhill in neutral, and don't change gears while going downhill. Save the wild rides for the amusement park."

Van De Veer reminds slope workers to check machine manuals for recommended adjustments to oil levels. Working on certain inclines, a sump that's not properly filled can leave the oil-intake high and dry and the engine starved for lubricant.

Clearing trees is another potentially dangerous job for which crawler dozers are remarkably suited. Make sure the dozer's falling-object protective structure (FOPS) is in good condition.

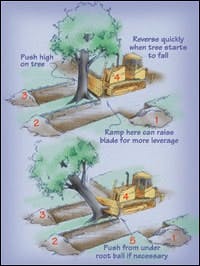

Look for a tree's natural direction of lean. It will be the best direction to push the tree. Adjust the direction of fall to avoid obstacles. Check the tree for dead branches that could fall.

Sever roots with a series of V cuts. VISTA recommends leaving the roots on the intended direction of fall untouched. They should act as a hinge, controlling the tree on its way to the ground.

Push the tree over with the center of the cutting edge, raising it high to improve leverage.

"When the tree starts to fall, reverse the dozer quickly to avoid the rising root mass," says VISTA's Tips video.

Large stumps can be uprooted in similar fashion. Although with no risk of a tree falling on the machine, you can V cut roots all around the stump for easier removal.

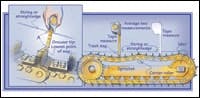

One key that operators hold to improving crawler-dozer efficiency has nothing to do with operating technique. It's maintaining track-chain tension, and it can reduce undercarriage wear by 50 percent. Caterpillar field surveys have found 20 percent of tracks too tight.

Operators are crucial to long undercarriage life because chain tension can require more-than-daily maintenance. Chain tension is judged by measuring sag — the amount that the track hangs down between the sprocket and the idler, or the idler and carrier roller. Operator's manuals include the recommended amount of track sag, and describe how to adjust chain tension.

There is no regular interval for checking chain tension. When mud starts packing in the sprockets — whether it rains, or the tractor hits a wet layer of earth, or the haul trucks start dumping wet spoil in the fill — someone has to stop and adjust chain tension.

Conditions may change again before the day's out — the spoil starts coming dry, or the tractor moves to higher ground, or the sun heats up and the wind starts to blow. To keep the loose chain from binding in front of the idler, the tension must be adjusted again.

| Training Resources | ||

| For more information about the range of operator training available from the sources in this story, contact the following companies: | Caterpillar Equipment Training Solutions (800) 962-6628 www.cat.com | |

| VISTA Training (800) 942-2886 www.vista-start-smart.com | ||