Motor graders have been an important tool for removing snow from highways and runways practically since their inception. But even before graders became self-propelled, their usefulness in clearing snow was seen—regardless of their practicality for the work.

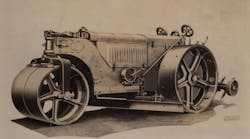

The accompanying photograph illustrates the problem in using a pull-grader for snow-removal work. Although the pull-grader was suited for smoothing dirt and gravel on a roadbed, moving thirty inches of snow and ice—as this Adams King Junior machine is doing in Colorado Springs, Colo.—was an entirely different matter.

The problem with moving snow with a pull-grader was the horses getting suitable traction against the combined slick surface and weight of the load on the blade. On a dry surface, traction usually would not be a problem, and the only resistance would be the load. Besides slippery surfaces, snow could be quite heavy, depending on water content, and it would be all but impossible to move with a horse-drawn grader if it had had a chance to freeze.

The teamster is seated at the front of the grader and controls the team of horses. The blade-man at the back operates and steers the machine. One teamster could usually handle a four-up team such as this, so it’s possible the second man up front may be there just to add weight and to keep the grader from riding up on the packed snow.

A major grader-design innovation—which unfortunately did nothing to give horses or pull-graders better traction on ice—was the leaning-wheel concept developed by J. D. Adams. As a grader’s blade engages its load, the weight of the load and the forward motion of the grader tend to force the blade away from the load as resistance increases. The leaning-wheel design allows the grader operator to tilt the grader’s front wheels (and sometimes the rear wheels) towards the load, allowing more of the machine’s weight to bear on the load and to counter resistance on the blade. These forces keep the blade engaged, allowing it to pick up and spread larger loads more efficiently. Graders continue to use the design, 129 years after it was invented.

J. D. Adams & Co. was acquired by LeTourneau-Westinghouse (L-W) in 1953. Recognizing the value of name recognition, the company continued to use the Adams trade name into the early 1960s. L-W evolved into WABCo, an acronym for L-W’s owner, Westinghouse Air Brake Co. The Wabco grader line was discontinued in the 1980s.

The Historical Construction Equipment Association (HCEA) is a 501(c)3 nonprofit organization dedicated to preserving the history of the construction, dredging and surface mining equipment industries. With more than 4,000 members in 25 countries, activities include operation of National Construction Equipment Museum and archives in Bowling Green, Ohio; publication of a quarterly magazine, Equipment Echoes, from which this text is adapted, and hosting an annual working exhibition of restored construction equipment. Individual memberships are $32 within the U.S. and Canada, and $40 elsewhere. Information is available at www.hcea.net, 419.352.5616, or [email protected].