Big trenchers existed in 1948 for digging distribution lines, but when utilities were being installed to individual houses, the trenchers were too large, and the job of digging trenches fell to men with picks and shovels. Ed Malzahn, a recent engineering graduate, noticed the hand labor taking place in his hometown of Perry, Okla. He envisioned that a compact, inexpensive digging machine could replace the picks and shovels. He took the idea back to the family business, where he and his father, Charles, manufactured products for the oil-drilling industry.

Malzahn and his father went to work designing a compact trencher. After testing and improving prototypes, they introduced the first production model of his service-line trencher, the DWP, in 1949. With a speed reduction box, the machine could be self-propelled using the same gear reducer that powered the digging device. Malzahn developed an inexpensive gear box that eliminated a complex system of sprockets, chains and belts. His was a planetary gear box using two primary gears of the same diameter, but with a different number of teeth on each gear. The result was two "sun gears" combined with three "planetary gears" that gave the needed reduction while fitting into a small package.

Malzahn also developed a simple way to bypass the planetary gear reduction so that the gear box became a direct drive. To do this, he needed a locking device to stop one of the primary gears. In the earliest gear boxes, he simply had an arm that stuck out, and the operator used a six-penny nail to stop the gear. By moving the nail from one hole to another, he could shift from dig to mobile. Malzahn later designed a shift plate that replaced the nails. From this point, the trencher underwent ongoing improvements.

In 1955, Malzahn's trencher, by now known as a Ditch Witch, was equipped with a patented endless conveyor digging chain design used on larger ditch-digging machines but on a much smaller scale. Small buckets with sharp, finger-like edges were mounted in sequence on an endless moving chain. It carried the bucket downward to chew out chunks of soil, then upward to dump the spoil in neat piles on the ground as they began the downward descent to bring up more dirt. A 4-inch-wide trench with a digging depth of 24 inches was the goal.

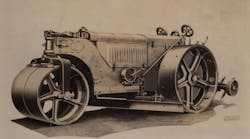

The operator sat on the machine and used simple lever controls to raise and lower the digging device. The air-cooled, 7-hp engine supplying power for the working end also gave the trencher mobility, transferring power through a belt drive. Riding on a welded frame with four small wheels, the trencher also had a ratchet drive that utilized the operator's arm and shoulder muscles to move the trencher forward while digging.

Charlie's Machine Shop became The Charles Machine Works, supplying Ditch Witch trenchers to dealers across the country. The company would go on to offer a line of horizontal directional drills and related products in addition to its trencher line. The latest introduction is the RT family of tractors, complete with trenching and vibratory plow attachments.

| Acknowledgements | ||

| Information supplied by The Charles Machine Works. If you are interested in historical equipment, consider a membership in the Historical Construction Equipment Association. Visit its website at www.hcea.net. | ||