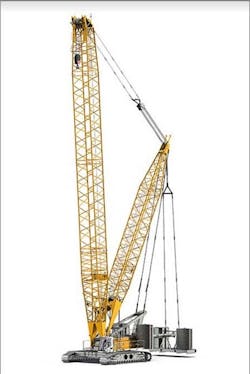

Liebherr LR 1300 SX Crawler Crane

The new Liebherr LR 1300 SX Crawler Crane has a lifting capacity of 661,387 pounds

(300 tons), and for heavy loads, the new model can be fitted with a derrick boom in combination

with an additional counterweight that can be hydraulically displaced. The LR 1300 SX

incorporates the Liebherr “Boom Up-and-Down Aid” assistance system, which indicates the

approach to the tipping border and automatically stops operation before the crane unintentionally

enters an unsafe zone. The system assists the operator in avoiding the danger zone without

activating the safety bypass switch, says Liebherr.

The new Liebherr also is fitted with wind sensors on the main boom and jib. Both the measured

wind speed and the actual crane configuration (boom length, boom angle) are taken into

consideration when calculating the current situation for the crane. When conditions become

potentially dangerous, the system gives a warning. The actual status is visible for the operator in

the cabin at all times. At wind speeds of (imperial mph) 10-16 m/s, the operator can adjust the

maximum lifting capacity through a simple selection on the control panel.

In addition to wind, ground load-bearing capacity and ground pressure also are significant factors

for the safe operation, says Liebherr. The Ground Pressure Visualization system on the LR 1300

SX calculates the current ground pressure of the machine in real time and compares it with the

specified safety limits of the relevant position. The ground pressure is displayed in the operator's

cab and the operator is constantly aware of whether the machine is situated in, or is approaching,

a critical area.

Three different driving speeds can be selected by the operator, and driving is always carried out

in “Safe Mode” with active Load Moment Limiter, says the company. The Liebherr Litronic

control system automatically adjusts the lifting capacities to suit the driving speed, when driving

with a load on the hook. For barge operation, the lifting capacities are automatically adjusted,

depending on the inclination of the barge.

The LR 1300 SX, belonging to the company’s newest generation of crane models, is approved

for personnel lifting. This mode is selected using a separate key switch. The EC type approval

certificate for the occasional lifting of persons means that local approval from an acceptance

authority is no longer required by the crane operator. The statutory emergency generator and

emergency controls required for personnel lifting are offered by Liebherr as a Plug-and-Play

solution. In case of emergencies, the crane availability can be restored within a few minutes, says

Liebherr.

The new crane is fitted with a new cabin, says Liebherr, with an air-conditioning system with

improved airflow, optimized field of vision, provisions for reduced in-cab sound, and an

operator’s seat with integrated heating and cooling.

Crane handling under special conditions, for example, in heavy-lift operations or in confined

spaces, says Liebherr, involves potential risks for man and machine. With the aid of the Crane

Planner 2.0 planning software, says the company, these sources of danger on the construction

site can be minimized. The system is programmed with actual planning data and the optimum

crane configuration is calculated based on the corresponding load moment limitation. All work

steps, from picking up to setting down the load, can be simulated on a PC or in virtual 3D space,

says the company, with the feasibility of checking the entire project in advance at the planning

table.