How to Defend Hydraulics from Dangerous Contaminants

Construction Equipment staff

Dust, dirt, water, metal: What do they have in common? According to Doug Jahnke, product marketing manager at Eaton Hydraulics, they could all doom a piece of heavy equipment. Even in small quantities, if these seemingly innocuous particles enter the hydraulic fluid of an excavator, backhoe loader, or one of your other valuable machines, components such as pumps and valves could begin behaving erratically and shorten equipment life.

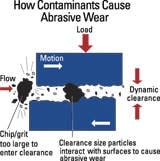

There are three types of hydraulic failure. Catastrophic failure occurs when a large particle enters a pump or valve causing a vane to jam. Intermittent failure happens when contaminants sometimes settle on a poppet valve, preventing it from closing. Degradation failure is usually the result of abrasive wear, corrosion, or surface fatigue on a component. For instance, when particulates get in between the clearance of the surfaces of a moving pump, they can rub up against the surfaces causing stress and cracks and even breaking parts of the pump into metallic particles.

“Because the metal is hard, it potentially could cause more abrasion and seriously damage a pump,” says Jahnke. “If the pump is operating at high pressures and high speeds, the metal particles could quickly cause it to go bad.”

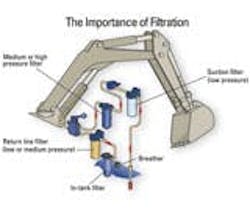

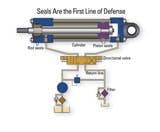

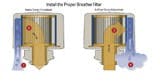

One way to make sure contaminants are eliminated from the hydraulic system is to regularly monitor filter elements and replace them when they are clogged. And while manufacturers sell equipment with a reservoir breather, they are not always equipped with a breather filter. Replacing the standard breather with one that has a built-in filter helps enormously to keep out contaminants.

Fluid sampling, says Jahnke, is necessary to determine what kind of contaminants have invaded the hydraulic system. For instance, if dust, dirt, or silica is found, this usually means ingression had occurred. In this scenario maintenance staff should install a breather filter on the reservoir. If dirt is found inside the components of a new machine, running the fluid through an offline filter or kidney loop should clean it out.

Hydraulic fluid should be sampled and analyzed on a regular basis. Depending on how frequently a piece of equipment is used as well as the pressure of its hydraulics, Eaton advises maintenance staff to take samples anywhere between two and six months. In order to determine whether the hydraulic fluid meets the target cleanliness, take a representative sample from the return line before the filter and send it to a qualified laboratory.