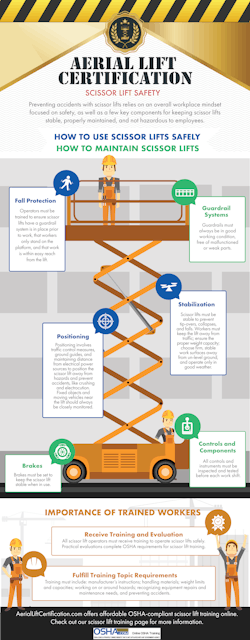

After investigating hundreds of scissor lift accidents, OSHA says that using proper fall protection, with the correct stabilization and positioning techniques, is the most effective way to prevent scissor lift accidents.

Employee training and employer vigilance are vital to a safe operating environment. Here are four cornerstones of training efforts, courtesy of AerialliftCertification.com:

- Fall protection

Unlike aerial lifts, scissor lifts don’t require the use of body harnesses and lanyards if there are adequate guardrails in place. Employers are responsible for training workers to check the guardrails before beginning work, to only stand on the platform and never on the guardrails, and to keep the work area within easy reach from the lift platform.

- Stabilization

With adequate training from employers, operators should always check to make sure the scissor lift is stable and not at risk of tipping over and collapsing. Both workers and employers can ensure scissor lifts are stable and safe to use by following the manufacturer’s instructions for safe movement, never moving the lift with the platform in the raised position, directing traffic and other equipment away from the scissor lift and work area, choosing work locations with firm level surfaces away from holes and drop-offs, and never working in poor weather conditions like high wind.

- Positioning

Properly positioning a scissor lift helps prevent injuries and fatalities caused by electrocution and being crushed. Employers must train operators to be cautious when moving a scissor lift near a fixed object, operating near a moving vehicle, working underneath electrical power lines, and passing under a fixed object like a door frame or beam. To avoid hazards, employers must use traffic-control measures near working scissor lifts and keep scissor lifts at least 10 feet away from live power lines.

- Maintenance

Keeping a regular maintenance schedule for scissor lifts will keep them safe and functioning for operators. Employers must ensure lifts are tested and inspected before every shift, guardrails are in good condition, and the brakes are functioning properly.

These practices will help keep hazards away from scissor lifts and their operators, but the right in-depth scissor lift training can help avoid accidents altogether. AerialliftCertification.com is a training resource, offering OSHA-compliant training that teaches workers proper fall protection, stabilization, and positioning for scissor lifts, as well as how to perform inspections and avoid hazards. You can download their handy chart (shown above) below for your job site, shop, or yard.

Download: Here