Editor's note: This article has been updated with the assistance of Sejong Ko, product manager—large excavators, Volvo Construction Equipment.

If you would, step into the cab of our imaginary 90,000-pound crawler excavator and make a hypothetical lift. The site requires your machine to sit with its tracks parallel to the trench, but it's set back from the edge as far as practical for safety. This means you'll initially be picking an 8-foot length of 30-inch-diameter concrete pipe over the idler end of the machine.

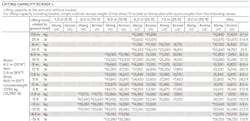

The lift radius (the distance between the center of the machine's swing bearing and the center of the load hook) is 15 feet, and the lifting eye on the back of the bucket is 5 feet above the ground when the rigging is pulled tight. At this starting point, the machine has 41,600 pounds of lift capacity, so the 3,600-pound pipe on the hook isn't much of a challenge.

But, as you ease the load 5 feet off the ground, thus raising the bucket's lift point to 10 feet, capacity diminishes to 35,000 pounds. As you swing 90 degrees, placing the pipe over the side of the tracks, capacity drops to 33,820 pounds. Now, as you arm out and boom down to center the pipe over the trench, you increase the lift radius to 20 feet and capacity plummets to 20,670 pounds. Then, as you touch the pipe to the trench floor, with the bucket's lifting eye now at 5 feet below grade, capacity is 18,340 pounds.

From start to finish, then, lift capacity has diminished by nearly 55% during this simple operation.

Use the excavator's lifting load chart

As our hypothetical lift demonstrates, the lift capacity of an excavator changes radically as the load position varies. It makes sense, then, when lifting with an excavator, to think through the lift and determine where the machine is least capable and whether the capacity at that point is sufficient to handle the load safely.

To perform this simple pre-lift analysis, you need to know the weight of the load and check the machine’s load chart, which should be mounted in the cab and legible from the control position. If, for some reason, the chart is not in the cab, make a copy from the operator's manual, laminate it, and keep it handy.

A hydraulic excavator’s load chart provides lift capacities for a range of lift-height/lift-radius coordinates, for both over-end and over-side lifting. Make sure the chart you use exactly matches your machine’s configuration. For example, rated capacities in some charts do not include the bucket. If so, and if you are lifting with the bucket on, then subtract bucket and coupler weights from the given capacities.

Always check chart footnotes for further qualifiers, such as the excavator work mode to be used when lifting, or to determine whether capacities are hydraulically or stability-limited. Use a larger machine if you're bumping up against rated capacities.

Making a pick without knowing how much weight is hanging on the hook is risky. Because excavators picking up heavy loads frequently handle concrete pipe and related structures, the American Concrete Pipe Association has done the industry a favor by providing weight charts online for round, elliptical and arch pipe, and for box-sections. But if you’re lifting less familiar objects — structural beams, for instance — a pocket-sized rigging manual that helps you calculate volumes and has weight charts for various materials would be a good resource to have on hand.

The computations of a pre-lift analysis

The exercise we’ve walked through highlights the practical necessity of consulting and understanding the excavator’s load chart. To further ensure safe and efficient lifting operations, it’s essential to perform a pre-lift analysis, considering the load’s weight and the machine’s configuration at every stage of the lift. The load weights in a machine’s load charts should denote whether a bucket is included, which must be taken into account.

Remember, the capacity from the load chart is not a static number — it’s a dynamic number that reflects the excavator’s capabilities in real time. Make it a habit to refer to the load chart frequently, and when in doubt, always err on the side of caution.